Grinding Machines

Meet the Okuma V920EX Vertical Lathe

The Okuma V920EX vertical lathe increases productivity by providing stable machining of thin and odd-shaped workpieces. With a max turning diameter of 36.22 inches and max turning height of 33.86 inches, this machine is capable of performing powerful, heavy-duty cuts, while the vertical orientation is the ideal platform for running thin-walled parts without distortion. The box-type base and column make a highly dependable, highly rigid structure and the headstock with flange construction minimizes the effects of thermal deformation and vibration, which ensures stable, accurate cutting.

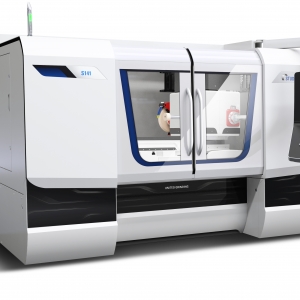

The NXT generation of tool grinding has arrived

The Star NXT tool grinder offers a focused design to deliver a maximized grind zone with our smallest footprint to date. Designed specifically with flexibility in mind, the NXT can be configured as an entry level regrind machine to a fully automated manufacturing solution.

For more information visit us at

https://www.star-su.com/tool-grinders/tool-cutter-grinders/nxt-tool-grinder/