Manufacturing and machining rotary tools with VOLLMER: efficient and precise!

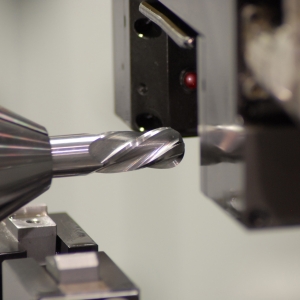

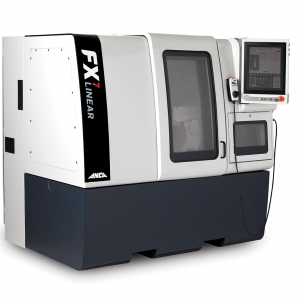

The VGrind 360, VOLLMER’s latest tool grinding machine, is equipped with enhanced travel distances in order to machine carbide tools up to a diameter of 100 millimeters. Thanks to its two vertical spindles, the VGrind 360 also allows for tried-and-tested multi-level machining. This enables tool manufacturers to quickly and precisely produce large numbers of milling cutters, drills, etc. whose blanks are made from either solid carbide or HSS (high speed steel).