Grinding

Wheel profiling machine from CUMI

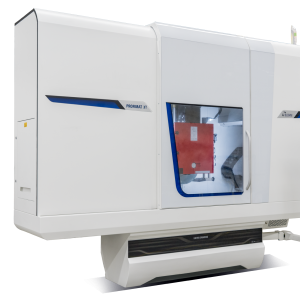

The CDM series wheel profiling machine from CUMI is ergonomically designed with operator friendly features for applications such as dressing and profiling of straight and convex diamond or CBN grinding wheels mounted on a wheel pack.