Tools that can mount a defense

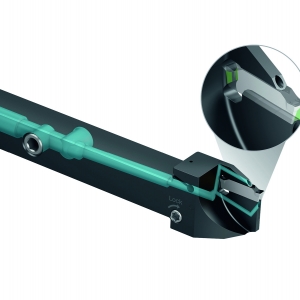

KYOCERA SGS Precision Tools (KSPT) recently introduced a new suite of 8 Picatinny Rail form tools. The innovative designs are inspired from largely successful high performance end mills in the current SGS portfolio. The SGS Picatinny rail portfolio has been carefully designed for material specific applications to service the firearms industry.

For more information, visit the Kyocera SGS Tools website.