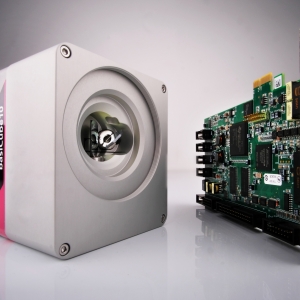

GF Machining Solutions unveils Laser S series machines

GF Machining Solutions introduced the AgieCharmilles Laser S series machines to its North American audience at a special event held earlier this month at the company's Lincolnshire, Illinois, location. On display was the Laser S 1000 U, which the company predicted would help manufacturers advance productivity, quality, design freedom, and time to market—all while reducing cost-per-part in markets such as automotive, packaging, and communications technology.