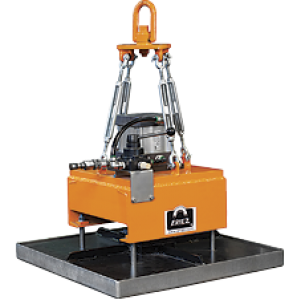

Parts Handling

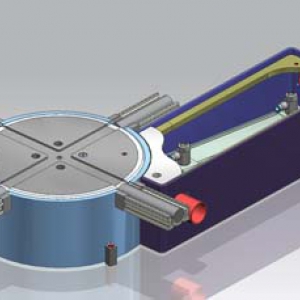

True mold manufacturing

Len Graham, Business Unit Leader, Rexam Mold Manufacturing, discusses the motivation behind the Buffalo Grove, Ill., company's decision to build a Mega Cell automated mold manufacturing system. Graham offers a detailed walk-through of the company's Mega Cell, which began operation in March 2013.