RoundTrack Floor Rail System

RoundTrack Floor Rail System

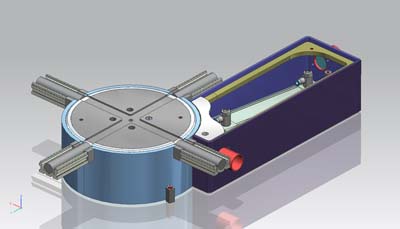

For a leading manufacturer of wind turbines, STROTHMANN has developed a pneumatic drive solution for the quadro turnstile.

For a leading manufacturer of wind turbines, STROTHMANN has developed a pneumatic drive solution for the quadro turnstile. The quadro turnstile, a crossing element in STROTHMANN's patented RoundTrack floor rail system for the in-house transport of heavy loads, consists of four turntables with a payload of 7 t each. The turntables can turn trolley rollers sideways, thereby making the trolleys change their driving direction. The first generation of quadro turnstiles for manual turns has been tested and proven at factories of international customers for several years.

The new pneumatic drive allows for even more flexible efficient intralogistics solutions. Developing RoundTrack components as per customer demand, STROTHMANN fulfills application-specific requirements. Another crossing element, the large turntable, can rotate entire trolleys by a 90 to 270 degree angle. In contrast, the trolleys crossing the quadro turnstile never change their orientation. If the transport trolleys are also used as workplaces, their orientation must be coordinated with machines and manufacturing stations, for instance.

Furthermore, some companies use them to transport overlong goods such as wind turbine blades; since two customized STROTHMANN trolleys are used for transporting such a blade, they have to keep their orientation even when they change the driving direction; with the quadro turnstile this can be easily implemented.