- Choosing a parts-marking method depends on the application

- Look Ahead: Trochoidal endmill (over)laps competition

- Look Ahead: Titanic robot, tiny tolerances

- Low-wattage lasers: faster, gentler, eco-friendly

- Factors affecting proper coolant application when grinding

- Lessons learned from threading nuts, bolts for gas turbines

- Process creates steel that's a-peeling

- CAD/CAM software for ultraprecision machining

- Explosive deburring ideal for complex parts

- Ask the Grinding Doc: Loading the wheel

- Shop Operations: Consider a 4-jaw independent lathe chuck

- Manager's Desk: Time to awaken the shop

- Machine Technology: Hybrid upsides and design considerations

- Lead Angle: Manufacturing and its myths

Cutting Tool Engineering Magazine

Cutting Tool Engineering magazine, published 12 times a year by CTE Publications Inc., helps manufacturing professionals enhance the productivity of their companies' cutting and grinding operations, and provides essential insights for machining professionals. Browse through our digital issue archive below and select the digital format you prefer: via our Cutting Tool Engineering app, a PDF file, or an interactive digital edition that can be viewed on any device by visiting digital.ctemag.com.

Get Your Printed Back Issues of CTE – Order Now!

Issue Archive

- The fundamentals of industrial sawing

- Look Ahead: an oscillating laser head for joining, cutting

- Look Ahead: a novel 3D-connector inspection system

- Productive Times: a high-torque conversion

- Productive Times: Productivity times savings

- Determining when a custom toolholder is a better option

- Machinist's Corner: New kid on the block

- Shop Operations: Get your bearings

- Abrasive waterjets now a viable 3D cutting option

- Get With The Program: Making the most of macros

- Rotary transfer machines: Eclipsing the past

- Machine Technology: Preparation automation pays

- Custom machines offer solutions standard ones sometimes can’t

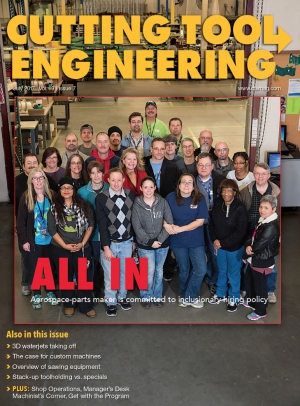

- One mission, two bottom lines

- Manager's Desk: Smart phone policies for shops

- Considerations when having taps resharpened

- Selecting a turret or gang tooling for a CNC lathe

- Tips for shops set on moving machine tools DIY

- Workholding solutions for 5-axis applications

- Lead Angle: Are we near the peak?

- Look Ahead: Point-and-click robot control

- Look Ahead: 3D printing picks up the pace

- Scanning a hypercar

- Productive Times: Kick out the jams

- Productive Times: From dovetails to dimples

- Trim waste with proactive environmental program

- Routing new composite materials requires new solutions

- Success detected for noncontact inspection

- Dry, tight fluid connectors require the right tool

- Ask the Grinding Doc: The question is academic

- Shop Operations: Catch a tiger by the tail

- Workholding: Building chucks to hold wheels

- Cleaning corrupt CAD models

- One year into the future at GE

- Colson Group reshores manufacturing

- Advancements in edge finders

- Toolmaker targets titanium

- Machine Technology: Building 'monster' machines

- Look Ahead: Fast process for depositing ultrahard coatings

- Look Ahead: A grinding machine designed for sintered ceramics

- Overview of parts deburring

- Small shops warm up to work cells

- Shop Profile: From pewter to ultraprecision CNC machine tools

- Demand rises for ultrahard-material cutting machines

- Machining 3D-printed metal

- Cutting tool and CAM collaboration

- Lead Angle: Rise of the soft machine

- Sandvik Coromant president promotes innovation

- Get With The Program: Cutting tool and CAM collaboration

- Machine Technology: Automating one machine

- Machinist's Corner: Ya' gotta love your vendors?

- Manager's Desk: The new normal

- Shop Operations: A better way to shorten screws

- Productive Times: Bonded by light

- Productive Times: Twin cutter boring head reveals more value over time

- Micromachining: The art and science of micro-moldmaking

- Micromachining: The essentials of manufacturing microtools

- Keep machine tools, shop floor data safe from hackers

- Choosing the right boring tool

- Rapid prototyping on a CNC machine tool

- MTU America: Machining parts for large diesel engines

- The Knee Mill: Still Standing

- Swiss Smarts

- Machine Technology: Fine points of modern sharpening

- Workforce: Finders Keepers

- Ask The Grinding Doc: Grinding steel shafts puts shop in 'fowl' mood

- Shop Operations: Workholder setup reduction

- Chicago-based innovation center to stoke manufacturing

- Productive Times: Brushing away chamfering

- Look Ahead: Stiff competition

- Look Ahead: Humanizing robotic movement

- EDM focus turns to throughput, ease of use, automation

- Hybrid machine tools for moldmakers

- 6 tips for improving turning operations

- Honing seen as capable, but underused finishing process

- Packaging with care

- Machine tool school days

- Kennametal CEO's take on simplifying production

- Reaping the benefits of lights-out machining

- Culture-changing tools

- OSHA’s SHARP program for small businesses

- Machinist's Corner: Cheap marketing can have an impact

- Get With The Program: Maximizing spindle time

- Machine Technology: To extend or not to extend?

- Shop Operations: Odds and ends

- Machinist's Corner: Talking safety

- Proper fluid management, filtration keep sumps cleaner

- Productive Times: Capacity relief

- Look Ahead: Remotely interesting monitoring

- Look Ahead: AI robot finds its way

- Lead Angle: Sounds of the season

- Cover Story: Pint-sized precision

- The age of aqueous cleaning

- Successful threadmaking requires the right gages

- Broaching a blind keyway with an inserted tool

- Live tooling capabilities on the rise

- 3 views of manufacturing

- Automating thread inspection on tubular goods

- Prize turns quick profit for waterjet machine winner

- Manager's Desk: Inspiration from immigration

- Machine Technology: Alternatives to hand-feeding machines

- Workholding: Secured by suction

- Shop Operations: Becoming familiar with a machine

- Ask The Grinding Doc: Decrease diameter, increase speed

- Productive Times: A mountain (bike) of chips

- Look Ahead: Low-temperature PVD coating

- Look Ahead: Calibration celebration

- Metalworking Product Review: February 2017

- Lead Angle: Manufacturing and millennials

- Cover Story: Through-coolant toolholders: efficient, economical

- Tips, techniques for nonperpendicular holemaking

- Experts assess current, future inspection technologies

- Enduring attachments

- Manager's Desk: Being the face of your shop

- Machinist's Corner: Lean from 30,000 feet

- Machine Technology: Financing your next machine tool

- Talking Shop: A Custom Grind

- Get With The Program: Optimization software saves time

- Shop Operations: CNC training begins with changing tools

- Productive Times: High-pressure holemaking

- Look Ahead: Burning hard metal

- Look Ahead: A combination tool for thread forming

- Lead Angle: Going to New Orleans

- A quick-start guide to centerless grinding

- Industry experts predict better, but not great year

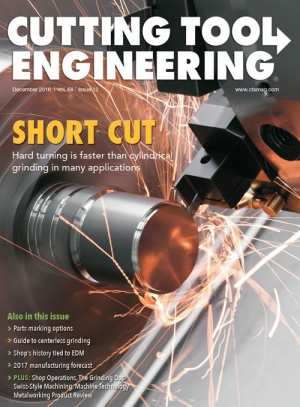

- Turning hardened materials presents challenges, opportunities

- Pros & cons of parts marking methods

- Tracing sinker EDMing back to its original spark

- Manager's Desk: Tougher & wiser in times of turmoil

- Ask the Grinding Doc: Setting up a lab

- Look Ahead: Industry 4.0, packaged

- Look Ahead: Another kind of multitask machine

- Swiss-Style Machining: Maximizing with multispindles

- Machine Technology: New life for an old machine

- Get With The Program: Achieving machining effectiveness

- Shop Operations: Cracking the code

- Productive Times: Taking a break from breakdowns

- Productive Times: Out with the old ...

Cutting Tool Engineering's annual Buyers Guide issue.

The October 2016 issue addresses the benefits of conversational programming for 5-sided machining. PLUS:

- Pros and cons of indexable tools

- Manager's Desk: Navigating customer portals

- Titanium Cutting Simplified

- 3D Printing, To Infinity and Beyond

- Lead Angle: In Screen We Trust

- Shop Operations: Becoming Familiar With Code

- Workholding: Mod Squad

- Machinist's Corner: Improving Daily Management

- Machine Technology: Sound Shakes Up Machining

- Get With The Program: Bring on the Heat

- Engineer-Speak

- Shop Profile: Seco Machine on the right track

- Finite element analysis in the supply chain

- Titanium Cutting Simplified

- 3D Printing, To Infinity and Beyond

Combination machines bridge the gap between manual and CNC equipment. PLUS:

- Lead Angle: Overcoming the skills gap

- Ceramic composite cutting tools: are they tough enough?

- The evolving technology of tool presetting

- Proper mist collection necessary for shop floor safety

- A tale of two cutting tools: solid and indexable-insert drills

- Net/Working with specialty subscription websites

- Get With The Program: Generate consistent and accurate pricing with cost-estimating software

- Machine Technology: Rotary unions help deliver coolant to the cutting zone

- Shop Operations: Benefits of becoming familiar with CAM software

- Machinist's Corner: IMTS is the place to check your wish list

- Hand-in Glove Robotic Technology

- (Polyn)urban Renewal