December 2016

Articles in this issue

Replace technologically obsolete production equipment

END USER: Mast Motorsports, (936) 560-2218, www.mastmotorsports.com. SOLUTION PROVIDER: Hurco North America, (800) 634-2416, www.hurco.com. CHALLENGE: Replace …

Taking a break from breakdowns

END USER: lllinois Carbide Tool Co. Inc., (800) 323-2414, www.crobaltusa.com, www.brakedrumtool.com. SOLUTION PROVIDER: Agathon Machine Tools Inc., (203) 730-8…

Another kind of multitask machine

The Look Ahead department in the December 2016 issue of Cutting Tool Engineering looks at a multitask machine for making injection molds.

Industry 4.0, packaged

The Look Ahead department in the December 2016 issue of Cutting Tool Engineering features a platform for Industry 4.0 connectivity.

Become familiar with CNC programming code

Presented here is the second part of a two-part series of columns about the importance of becoming familiar with CNC programming code. The following describes …

Maximizing with multispindles

Before CNC lathes, most high-volume turned parts were made on multispindle, cam-driven screw machines. Setup times were long, and great skill was needed to des…

Achieving machining effectiveness

In the first part of this two-part series, I looked at what actually happens in the cutting zone and how that knowledge allows end users to select the best pos…

New life for an old machine

Are you about to scrap an old machine tool and replace it with a new one? Before you do, consider what could be a much less expensive way of getting a better m…

Tougher & wiser in times of turmoil

While attending IMTS in September, it was nice to meet fellow machine shop owners and managers, many of whom expressed optimism and reported a robust year for …

Setting up a lab

The Grinding Doc fields the following questions: 1. The grinding wheel manufacturer I work for wants to set up a basic lab for testing wheels and different Al2…

Tracing sinker EDMing back to its original spark

Electrical discharge machining (EDMing) goes by many names—burning, spark machining, spark eroding, vaporizing—but they all refer to variations on the same pro…

Pros & cons of parts marking methods

Often dictated by the production environment, part quantities and part function, the selection of a parts marking method presents a variety of choices—each of …

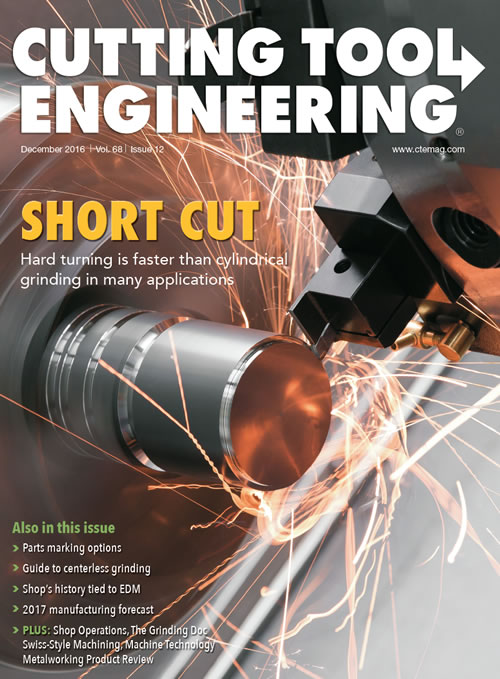

Turning hardened materials presents challenges, opportunities

Opinions vary on the definition of hard turning. Some industry experts say it's the single-edge cutting of hardened steels from 58 to 68 HRC, while others sugg…

Industry experts predict better, but not great year

Industry experts predict better, if not yet spectacular, times for manufacturers in the coming year.

Basics of centerless grinding

For those "making chips" every day, centerless grinding may seem mysterious, but it's a fairly straightforward process. This article will discuss how it works,…

Going to New Orleans

There was plenty to see, eat, drink, hear and learn at the United States Cutting Tool Institute's 2016 Fall Meeting, held in New Orleans Oct. 15-17.