FOBA laser marker handed over to university in Tuttlingen

FOBA laser marker handed over to university in Tuttlingen

The Innovation and Research Center (IFC) Tuttlingen of the Hochschule Furtwangen University of Applied Sciences (HFU) and FOBA Laser Marking + Engraving have officially launched their innovation cooperation for medical technology. At a ceremony on March 20 in the new rooms of the IFC on Katharinenstraße, a modern laser marking system was presented, which is now available to the university for its research as well as interested parties from the industry for demonstration purposes.

Article from FOBA Laser Marking + Engraving

The Innovation and Research Center (IFC) Tuttlingen of the Hochschule Furtwangen University of Applied Sciences (HFU) and FOBA Laser Marking + Engraving have officially launched their innovation cooperation for medical technology. At a ceremony on March 20 in the new rooms of the IFC on Katharinenstraße, a modern laser marking system was presented, which is now available to the university for its research as well as interested parties from the industry for demonstration purposes.

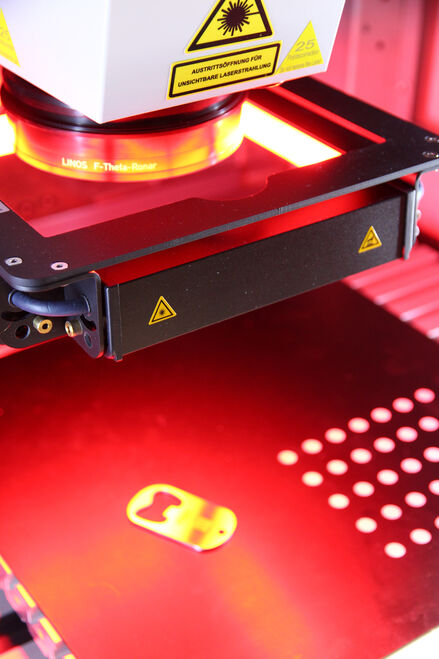

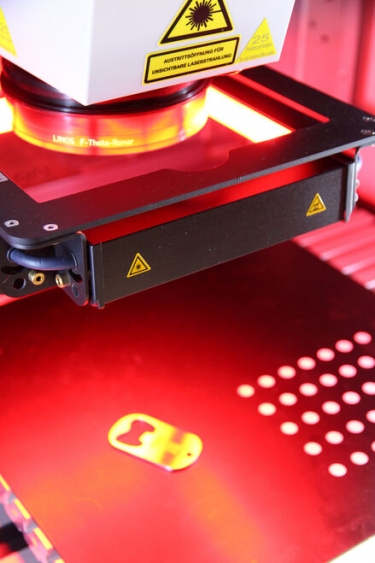

The combination of research and industrial application is in the center of the work on the Tuttlingen campus of HFU, in the form of cooperations between the IFC and manufacturing companies as well as in education. Numerous industrial plants are available in laboratories and the IFC's own extensive machinery. With the fiber laser marking system M2000-P, which FOBA has handed over, the researchers now also use a fully equipped laser marking machine of the latest generation.

Laser head of FOBA M2000 laser marking station with vision system and software feature Mosaic for the automated mark alignement without product fixtures.

"75 percent of our work is applied research," said innovation manager Regina Storz-Irion on the occasion of the inauguration, who, together with Professor Griselda Guidoni, established contact with FOBA. "The goal of our cooperation with industrial companies is to create benefits for the companies in the region. It also happens by putting science into practice, for example in the form of student's theses. "

In two lectures, it became clear from a scientific and practical perspective how the labeling of different surfaces using laser technology works and what the technical challenges are. Materials scientist Professor Griselda Guidoni researches which laser parameters are most suitable for which material. To achieve durable and high-contrast inscriptions, the laser beam must change the surface in such a way that, in addition to the desired marking effect, there is no damage to the material.

Depending on the properties of a metal or plastic, the appropriate laser parameters such as wavelength or pulse duration are determined individually. "Our systems offer the advantage that the parameters for certain materials are already integrated in the software," explained Christian Söhner from FOBA. "This way, the user can fall back on empirical values when setting up a marking job." The camera integrated in the marking system also contributes to safe and error-free marking.