Grinder option tackles non‐round punch and pin jobs

Grinder option tackles non‐round punch and pin jobs

Rollomatic, the original inventor of pinch/peel grinding machines, showcased a new model of pinch/peel machine at the recent Eastec show that can perform non-round grinding of punches and pins.

Rollomatic, the original inventor of pinch/peel grinding machines, showcased a new model of pinch/peel machine at the recent Eastec show that can perform non-round grinding of punches and pins.

Rollomatic, the original inventor of pinch/peel grinding machines, showcased a new model of pinch/peel machine at the recent Eastec show that can perform non-round grinding of punches and pins.

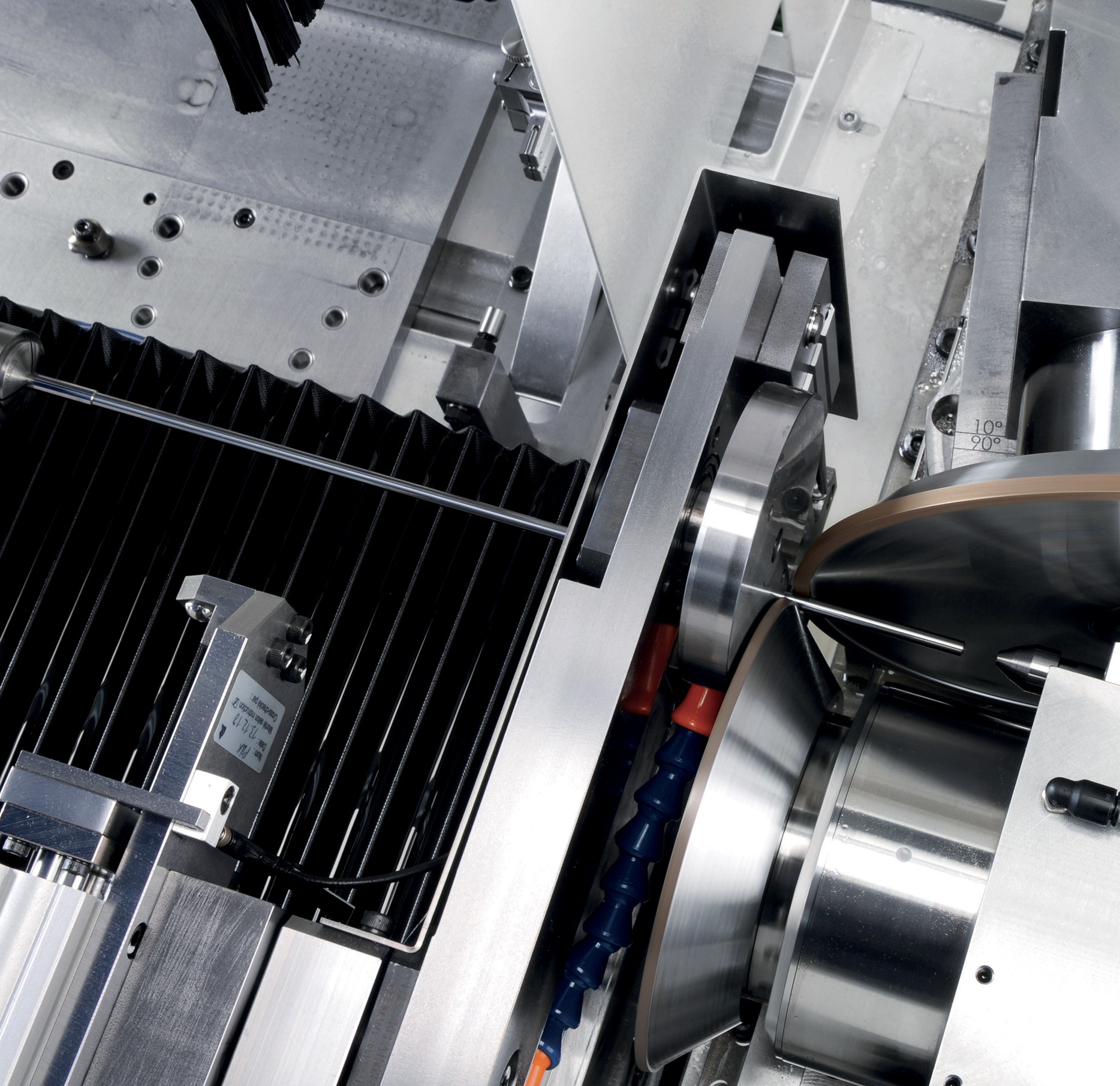

The ShapeSmart model NP50 is designed and dedicated for cylindrical grinding of carbide, HSS and stainless‐steel blanks and components with emphasis on highest achievable surface finish and concentricity.

The patented process for grinding non‐round parts includes full pinch/peel grinding which ensures extremely high tolerances, form accuracy and the lowest TIR achievable. This is particularly important for exc eptionally thin and long parts. Oblong punches, form punches, squares out of center, corner radiuses and any other shape can be produced with this method.

eptionally thin and long parts. Oblong punches, form punches, squares out of center, corner radiuses and any other shape can be produced with this method.

This machine is also suited for blank preparation of cutting tool blanks in the industrial, medical and dental markets.

For more information on Rollomatic products and services, visit www.RollomaticUSA.com.