Metal Supermarkets names ‘Metal My Way’ winners

Metal Supermarkets names ‘Metal My Way’ winners

Metal Supermarkets, a supplier of small-quantity metals, named the six winners of its 10th annual Metal My Way contest.

Metal Supermarkets, a supplier of small-quantity metals, named the six winners of its 10th annual Metal My Way contest.

This year's competition received over 830 submissions from across North America and the United Kingdom with projects ranging from small engine models, car restorations, commissioned art to large-scale renovations and construction projects. Metalworking professionals and enthusiasts were encouraged to submit their metal-made projects during September for a chance to win prizes.

This year's grand prize winner is Cindy Chinn from Chester, Nebraska, United States, for her submission entitled 'The Peacock'. Created over the course of a year, Cindy worked with copper sheets over a framework of rebar and pipe to create the body of peacock. Fabricated mild steel rod and scrap metal were used to construct the legs and head while the wings consist of copper rods and tubing.

Additionally, the outstanding projects in five categories received a Lincoln Electric Weld Pak. The category winners are:

Best Vehicle Project: James Frankland purchased metal from the Metal Supermarkets store in Southampton, United Kingdom to build his 'Homemade Submarine'. James set about to fulfill a childhood dream and engineering challenge when he first took on the build. Over six years, the creation involved welding, cutting, machining, and general fabrication. After the design was certified, James' submarine was rated to 100 meters diving depth.

Best Artistic and Design Project: Nancy Bole of Wichita, Kansas – 'The Indian' – Nancy created this project based on her affinity to the Cherokee and Cree tribes. She spent almost six months finishing the creation using a plasma table to cut the metal, before welding and sculpting the crown, feathers, and head.

Best Furniture and Home Project: Deborah Mitchell of Easley, South Carolina, – 'Security Doors' – Over 100 hours of work went into creating Deborah's project that featured brushed copper sheeting, steel, steel rods, and copper wire. To make the commission for an art collector client, Deborah employed a variety of tools including tube bender, angle grinder, Dremel tool, hammer, and welding tools.

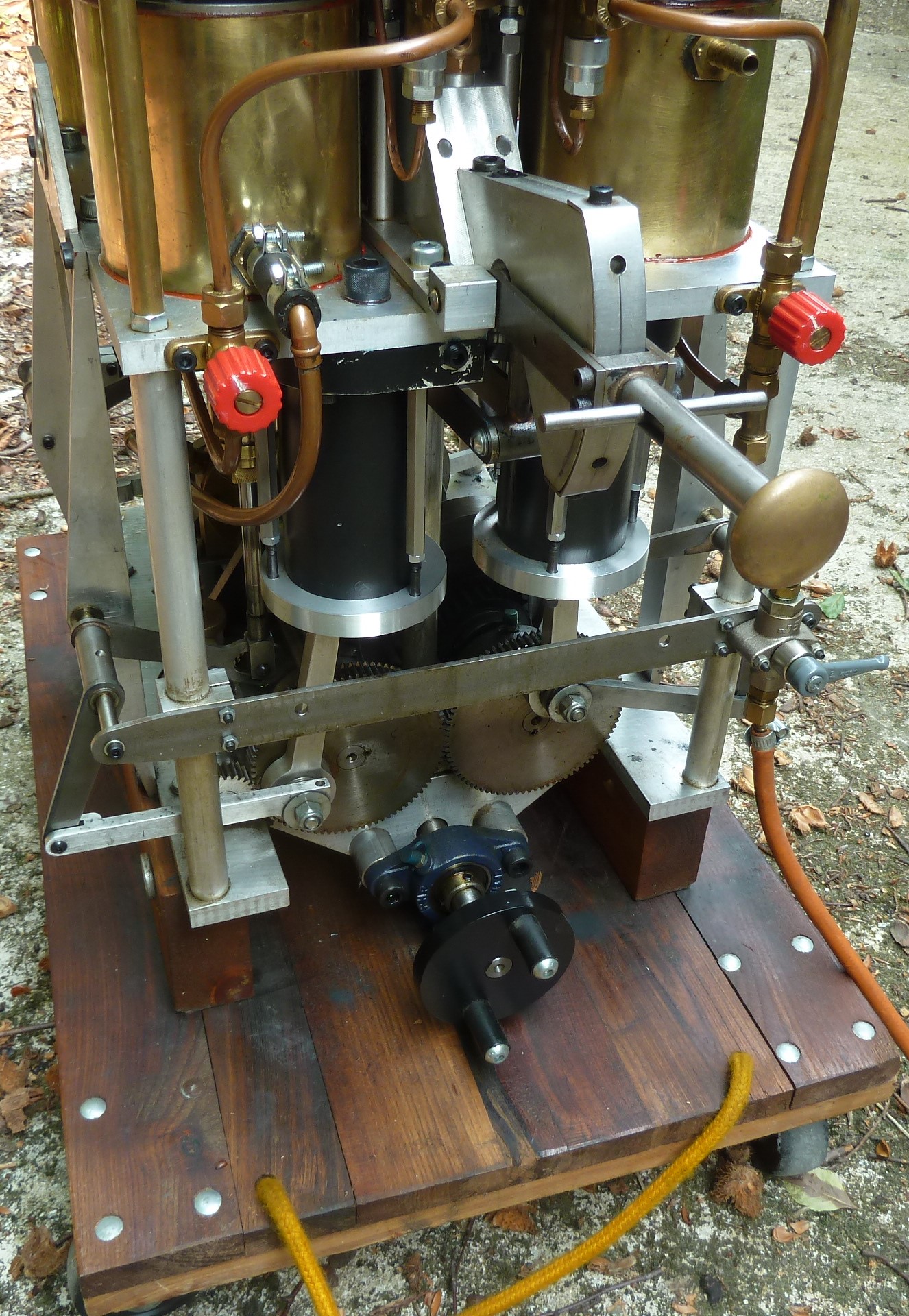

Best Industrial or Shop Project: Keith Broomfield purchased metal from the Metal Supermarkets store in London to build his '4 Cylinder Hot Air Engine'. With an interest in small steamboats plus open boilers and engines, Keith spent almost five years creating his four-cylinder configuration featuring two crankshafts geared together. Using mild steel, stainless steel, silver steel, brass and phosphor bronze, Keith welded and soldered his own design using parts he created.

Best Knife Project: Isaiah Chevalier purchased metal from the Metal Supermarkets store in Anchorage to create 'Snake Head Dagger'. Starting from the attitude of wanting to make something 'different and unique, Isaiah took about 40 hours to create 80 layers of 15n20 carbon blade steel and 80crv2 high-carbon tool steel for his project. He forged the wrought iron guard featuring a cactus handle with brass inlay topped off with a fine point to resemble a snake's fang.

Winners were selected based on complexity, detail, and intricacy; scale; uniqueness and creativity; craftmanship; quantity of metal used; and ingenuity. Selections were made by a committee consisting of Metal Supermarkets corporate staff.

"It was another challenging year to pick the winners from all the incredible projects submitted to this year's Metal My Way contest," said Stephen Schober, President and CEO of Metal Supermarkets. "With the ongoing need of skilled trade works across North America, it's always encouraging to see all the people who have the skills to create amazing metalwork across Canada, the US and the UK. Congratulations to Cindy and all of this year's winners."

In addition to Metal Supermarkets, this year's Metal My Way was sponsored by Haco Atlantic, Inc., Space Aid Manufacturing, Cosen Saws, and Ferric Machinery.

Winning metal projects can be viewed at metalmyway.com where further details, including sponsor information, can be found.