New metrology program at Fullerton College

New metrology program at Fullerton College

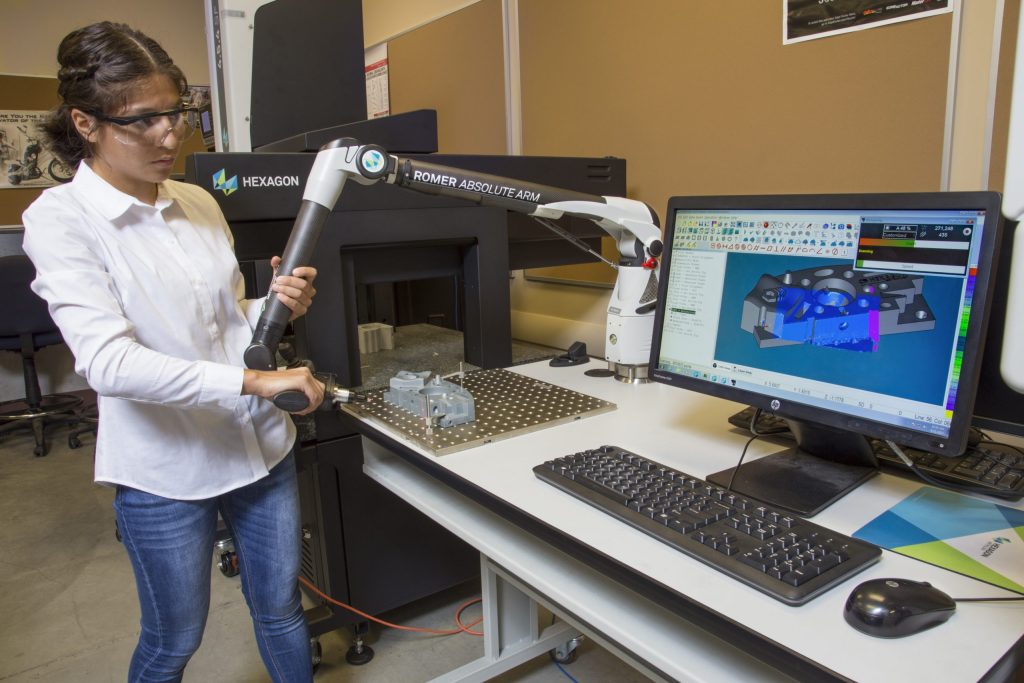

Hexagon Manufacturing Intelligence, North Kingstown, R.I., announced that its portable and stationary coordinate measuring machine technologies will be integrated into a new metrology program offered at Fullerton College in Fullerton, Calif.

Hexagon Manufacturing Intelligence, North Kingstown, R.I., announced that its portable and stationary coordinate measuring machine technologies will be integrated into a new metrology program offered at Fullerton College in Fullerton, Calif. Fullerton College is one of the largest and best-equipped machinist trade schools in California. Starting fall 2018, students will learn how to use a wide array of measurement and inspection tools, including ROMER Absolute arms, laser scanners, CMMs and more. The new curriculum will enable students to study the science of measurement and acquire job skills that are in high demand by science laboratories and industries using advanced manufacturing technologies, such as aerospace, defense, automotive, medical and power generation. Students can begin work toward a metrology certificate of achievement with several compulsory courses available.

The metrology program is a natural extension of the machine technology curriculum already in place at Fullerton College. Course study will cover fundamental metrology concepts and offer hands-on usage of shop floor CMMs and portable measuring machines for practical measurement and inspection operations conducted in machine shops and manufacturing cells. The ROMER articulating arm is a versatile measurement tool designed to meet the needs of almost any measurement application, whether scanning or touch-probing. This portable CMM provides the foundation for Fullerton College's rigorous program of electives designed to prepare students for scientific research and today's data-driven manufacturing environments. The ROMER Absolute arm with integrated RS4 laser scanner will provide the means for precision 3D data capture across a range of surfaces and applications.

"Our new metrology program will add additional certificates and skills competencies, making our students even more valuable and employable within our local industries," said Dan O'Brien, instructor and machine technology department coordinator at Fullerton College. "Manufacturing companies are challenged with filling employment positions that utilize new digital manufacturing and measuring technologies. This program intends to help fill this critical gap."

"Hexagon Manufacturing Intelligence is very pleased to support the new metrology program being offered next year at Fullerton College, a premier academic institution that strongly supports vocational programs," said Zvonimir Kotnik, business unit manager of portable products at Hexagon Manufacturing Intelligence. "Measurement professionals will be in very high demand for the foreseeable future. Metrology education can open many career doors and introduce students to data-driven manufacturing and other diverse applications requiring 3D data for analysis, measurement, automation alignment, visualization and more. The ROMER Absolute arm with integrated scanner is the ideal teaching toolset as industry uses this technology for point-cloud inspection, product benchmarking, reverse engineering, rapid prototyping, virtual assembly and CNC milling."