Thomson releases first collaborative 7th axis with collision detection

Thomson releases first collaborative 7th axis with collision detection

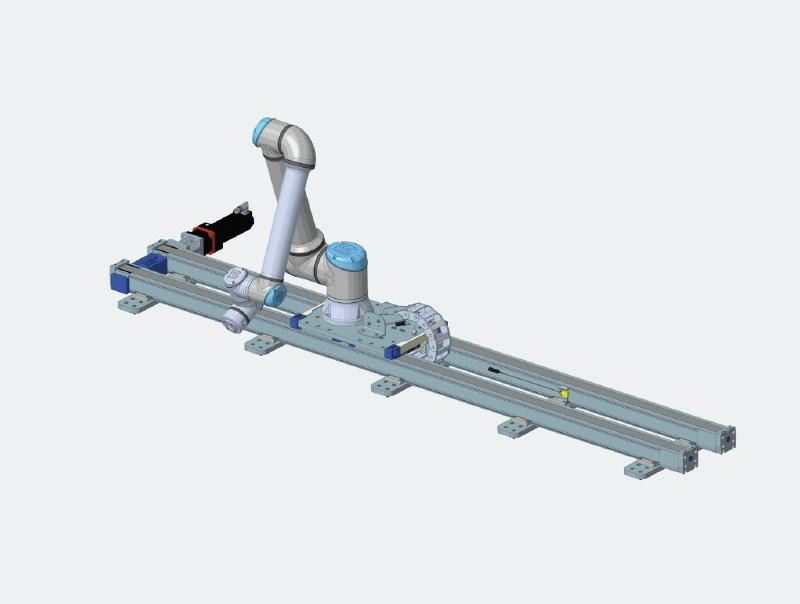

The Movotrak CTU 7th axis robot features collision detection settings for programming and control benefits. Also, an industrial robot transfer unit (RTU) was launched, which can be integrated with a user's preferred motor and drive.

Thomson Industries, a leading linear motion control solutions manufacturer, has released what it says is the first-ever true collaborative extension of cobots. The Movotrak CTU 7th axis features collision detection settings for groundbreaking programming and control benefits. An robot/" data-glossary-id="141812" data-glossary-teaser="Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring dev…" title="Robot designed for industrial use. Primarily used as a material-handling device but also used for changing tools, assembling parts, and manipulating special tools and measuring dev…" aria-label="Glossary: industrial robot">industrial robot transfer unit (RTU) was also launched, which can be easily integrated with a user's preferred motor and drive.

Adding a horizontal operating range of up to 10 meters, the Movotrak cobot transfer unit (CTU) sets itself apart with collision detection that stops the cobot when encountering an obstacle, facilitating collaboration and increasing productivity.

"With the extension of the collaborative functionality along the 7th axis, manufacturers can deploy cobots to work more closely and flexibly with humans. Using the same cobot for more than one workstation boosts productivity and extracts maximum value from the initial cobot investment. We are thrilled to bring this game-changing addition to the world of collaborative robotics," said Kyle Thompson, Product Innovation Manager at Thomson.

Redefining collaborative robotics

Also known as a range extender, the Thomson Movotrak CTU 7th axis features a Kollmorgen servo motor and linear-unit-driven guide rails that move a cobot assembly from one task location to another. However, unlike all other 7th axes, the Movotrak CTU has collision detection functionality like a cobot joint. Users adjust collision sensitivity settings on a control tablet during setup, and the Movotrak CTU motor drive and digital I/O manage the collision monitoring and shutdown.

The collision detection system also monitors current continuously, detecting position errors in the motor, and providing comprehensive anti-collision capabilities along the entire 7th axis. The system includes a small reverse-move feature that eliminates pinch points following a stop.

The Movotrak CTU 7th axis integrates seamlessly with many cobot sizes and brands, including Universal Robots (UR), which allows all programming to be done directly through a URCap interface on their UR Teach Pendant. All collision monitoring and safeguard logic runs in the Thomson drive, so bandwidth competition with the UR controls is minimal.

Similar to the freedrive of cobot joints, the Movotrak CTU 7th axis freedrive functionality enables hand-driven setting of linear waypoints during programming. Users manually slide the cobot where they would like it to be in a sequence along the 7th axis and register that with a simple push button.

Robust and versatile

The Movotrak CTU 7th axis distinguishes itself through its innovative dual-linear unit solution, delivering exceptional moment load capacity and stiffness. This design ensures peak performance, even when fully extending the cobot arm, setting a new standard for reliability. Moreover, it offers unparalleled flexibility.

The 7th axis can be seamlessly mounted in a horizontal, inverted, or wall-mounted configuration, making it an adaptable choice for diverse applications. Notably, the Movotrak CTU 7th axis is well-equipped for compatibility with even the largest cobots, such as the UR20 and UR30, meeting the specific needs of Thomson customers and responding to the high demand for such configurations.

Thomson also released an industrial RTU that allows users to equip their robotic applications with a 7th axis. ">

Thomson also released an industrial RTU that allows users to equip their robotic applications with a 7th axis. ">Integration alternative for industrial robots

For those with a preferred servo/auxiliary axis motor and drive, Thomson is also releasing a new industrial RTU, which allows users to quickly and easily equip their robotic applications with a 7th axis. With a Thomson RediMount motor mounting adapter kit included, users can integrate their motor in less than a minute and use their own robotic controller to take advantage of the RTU. Compatible with many robot brands and sizes, the industrial RTU features the same dual-linear-unit design and carriage-mounted mounting plate as the Movotrak CTU to ensure optimal precision for your application.

Available immediately, the Thomson Movotrak CTU 7th axis ships as a kit, including the linear units, gearhead, motor, drives, control box, software, end-of-stroke limit switches, and cable management. The Thomson industrial RTU is also available and includes dual linear units, gearhead, motor mounting adapter kit, mounting plate, end-of-stroke limit switches, and cable management.