Industry News

07/17/2019

Vallen Distribution Inc., a leader in indirect industrial supplies, technical safety services and integrated solutions, has named Rick Harris as director of metalworking. Harris will be responsible for all metalworking-related functions, including training and marketing, and managing relationships with suppliers and metalworking specialists.

07/17/2019

Panel building on machine tools is no longer as simple as wiring a few components and calling it a day. Now, there are more deadlines, cost pressures, standards, new directives, plus an increasing pressure to innovate. Besides commonly encountered problems related to time, cost, compliance and quality, there is also an increased degree of automation in the pre-fabrication of cables and the automated production of sheet metal parts.

07/17/2019

The Hypertherm Owners’ Philanthropic Endeavors (HOPE) Foundation, a public 501(c)(3) organization, is partnering with the Institute of American Apprenticeships at Vermont HITEC on a pilot program to teach software development to high school juniors and seniors.

07/16/2019

Bridging the manufacturing skills gap calls for innovative training approaches to equip employees with the new technical skills they need to succeed in the industry. Simulation training is one approach that has the potential to recruit and onboard employees and provide them with the needed skills.

07/16/2019

Local microfactories democratize innovation, making production more readily available to entrepreneurs, inventors and makers.

07/16/2019

Swift work by NVision Inc. helped a major U.S. airline quickly repair a bird-damaged Boeing 737 wing and return the restored jet back to flight in just two days. The rapid turnaround helped the airline avoid the financial losses typically incurred by grounding aircraft.

07/11/2019

MxD and AT&T announced they are working together to help accelerate the deployment of 5G to the U.S. manufacturing industry. AT&T is collaborating with MxD (Manufacturing times Digital) to install 5G technology and Multi-access Edge Compute (MEC) within MxD’s Chicago-based innovation center dedicated to advancing manufacturing innovation.

07/11/2019

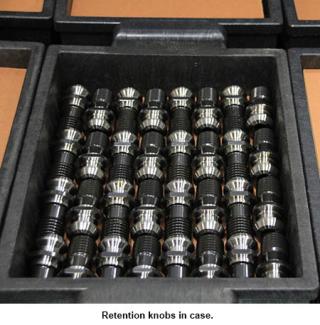

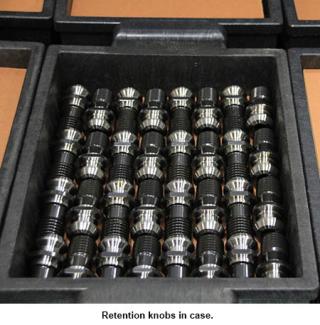

For years, collet-type toolholder assembly and setup have relied on cumbersome, error-prone manual methods that waste time and money. From a wall filled with adjustment charts, operators reference torque values based on specific collet series holders and tool diameters. Then they must locate the appropriate torque wrench, unlock it, set its torque level and re-lock it before tightening a toolholder’s collet retention nut. This complex procedure leaves many shops scrambling to regain precious lost production time – and often leads to inaccurate torque settings that can damage toolholders and, in some instances, impact workpiece precision negatively.

07/09/2019

Two statistics seem unrelated but, taken together, say something significant about New York City’s future as an engine of opportunity, innovation and equity. The first is that manufacturing lost more jobs than initially estimated and now accounts for only 69,000 jobs in the city, or 1.5% of the total. The second is that information jobs grew by 6% to about 200,000.

07/09/2019

Most CNC machine shops face the same problem: The programming office is backed up, so how can machine tools keep running? Wooster, Ohio-based NobleTek uses Vericut toolpath simulation and optimization software from CGTech Inc., Irvine, California, to ensure smooth operations and prevent late deliveries, lost productivity and unhappy customers.

07/08/2019

Sandvik Coromant is strengthening its capabilities in digital manufacturing by signing a strategic research agreement with PARC, a Xerox company, world-renowned innovation center. PARC will provide Sandvik Coromant with a footprint in Silicon Valley and expert resources for R&D in the field of digital manufacturing.

07/05/2019

umati - universal machine tool interface goes live at EMO Hannover 2019 from Sept. 16 to 21 with an exciting presentation. "Around 50 machine tool manufacturers from all over the world will be joining forces to show how umati makes machine data usable," says Dr. Alexander Broos, umati project manager and head of research and technology at the EMO organizer VDW (German Machine Tool Builders’ Association). Trade show visitors will experience live the benefits the standardized interface offers.

07/03/2019

No matter what kind of manufacturing facility I’m in, there’s one thing I hear over and over when I ask workers on the floor about indirect inventory: They want it available—no matter when, no matter how frequently or infrequently they need it.

07/03/2019

ARCH, a Jordan Company platform company that is focused on manufacturing precision cutting tools, precision machined components and medical implants and instruments, has acquired Siem Tool Co., Latrobe, Pennsylvania. Siem Tool is a manufacturer of customized solid-carbide drills, endmills, reamers, thread mills and form tools. Siem Tool will join ARCH’s Cutting Tools division.

07/01/2019

Although Microlution Inc. has been based in multiple locations since the builder of micromachining centers was founded in 2005, the company held its first grand opening event June 28 as part of GF Solutions Days USA 2019. The first location for Chicago-based Microlution, which has operated as a subsidiary of GF Machining Solutions since 2016, was in Andy Phillip’s apartment in Champaign, Phillip said. He is one of the company’s founders and now head of laser micromachining.

07/01/2019

ARCH Cutting Tools is facing the same talent shortage as the cutting tool industry overall, but the company is meeting the challenge with an aggressive workforce development strategy aimed at Millennials and Generation Z. In partnership with Delta College, ARCH Cutting Tools hosted an Introduction to Machine Tools Forum at its Flushing, Michigan, facility June 6 for five students interested in careers as machinists.

06/26/2019

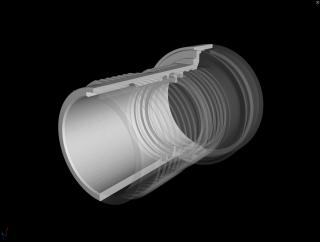

The ability to “see through” a solid object was once thought to be a tool of the future, or a power belonging to Superman–but the technology is here today, and more widespread and accessible than you may have thought. Until recently, the technology of CT imaging was only available for use in medical settings. Over the last several years, it has found a new home in the world of manufacturing, and is opening up myriad opportunities never before available.

06/26/2019

High-speed machining — in excess of 20,000 rpm — often is used in aerospace when machining exotic alloys and hard metals, such as titanium. At these speeds, precise, secure seating of tapered toolholders in the spindle becomes even more critical. Failing to pay attention to this single detail can lead to decreased productivity, less precise machining, reduced tool life and damaged workpieces.

06/26/2019

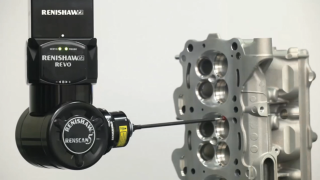

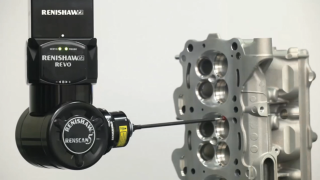

All machining operations have inherent variation caused by machine positioning errors, material variances, fixturing, tooling load and thermal changes. Many companies employ metrology at the end of machining to ensure that good parts go out the door, but it does little to improve manufacturing efficiency. Applying metrology before and during machining processes keeps operations in tight control, significantly improving process yield and final part quality at a much lower cost of production.

06/26/2019

McPond, a peer-to-peer platform based in Chicago, lets manufacturers list their idle machines for rent.