Industry News

02/05/2019

Sunnen Products Company expands its direct sales operations to Canada with establishment of a Canada-based sales and support team.

02/05/2019

RAMSEY, NJ – Manufacturer and solutions provider of fully automated centerless and other types of turnkey precision grinding systems, Glebar Company, announced that it has added two more members to its Sales Team; Mark Kraus and Anthony Pickering.

02/05/2019

Birmingham, AL – Motion Industries, Inc., a distributor of maintenance, repair, and operation replacement parts and a wholly owned subsidiary of Genuine Parts Company, announced today the promotion of N. Joe Limbaugh to the position of Senior Vice President of Supply Chain, Operations Support and Marketing, effective January 1, 2019.

02/05/2019

Birmingham, AL – Motion Industries, Inc., a distributor of maintenance, repair, and operation replacement parts and a wholly owned subsidiary of Genuine Parts Company, announced the promotion of Randall (Randy) P. Breaux to President on December 12, 2018.

02/04/2019

Memphis, TN, U.S.A. – Methods Machine Tools, Inc., a North American supplier of precision machine tools and automation, held a Ribbon Cutting Ceremony to announce the opening of its new 7,000 sq. ft. Memphis Technology Center at 6700 Fletcher Creek Cove in Memphis, Tennessee.

02/04/2019

SUDBURY, MA. U.S.A. – Methods Machine Tools, Inc. (www.methodsmachine.com), a North American supplier of precision machine tools and automation, has announced that Mr. Jon Dobosenski has been appointed as General Manager of Methods' new Memphis Technology Center.

02/04/2019

Wuhan Hangda Aero Science & Technology Development Co., Ltd. develops high-precision components for the aviation industry at the Dongxihu site in China.

02/04/2019

Hermitage PA - Solar Atmospheres is pleased to announce the addition of Timothy C. Fish to our sales team, as Regional Sales Manager at Solar Atmospheres of Western PA.

02/04/2019

Souderton, PA – Solar Atmospheres recently awarded the title of CEO Emeritus to Roger A. Jones, FASM.

02/04/2019

Greenville, SC - Solar Atmospheres South Carolina facility proudly announces that Mike Paponetti has accepted the position of Sales Manager.

02/01/2019

From January to November 2018, the Institute for Supply Management reported that Buffalo, New York's Purchasing Managers' Index was consistently higher than the national PMI, averaging 72.4, which was more than 10 points above the national average. With a long history as a manufacturing hub and recent growth, it's not surprising that there are many great manufacturing jobs available in the community. Moreover, the types of jobs advertised are changing. Instead of traditional manufacturing positions, employers are hiring for roles like machinist and programmer, which usually offer higher wages and better advancement opportunities.

02/01/2019

Today, the WMF Group, which was founded in 1853 as Metallwarenfabrik Straub & Schweizer and has been part of the French SEB Group since 2016, represents the best in cooking, drinking and dining. More than 2,200 employees at the Geislingen headquarters and the nearby Hayingen plant alone are engaged in the development and production of high-quality cookware and cooking knives.

01/29/2019

Lightweight Innovations For Tomorrow, a national manufacturing innovation institute, announces its Heller FP 6000 5-axis machining center has been installed, and is ready for use, at its research and manufacturing facility in the Corktown neighborhood of Detroit. With the installation of this machine, Heller is assisting LIFT and its members to further develop next generation processes in lightweight metal manufacturing.

01/29/2019

A metal blisk or heat exchanger component can certainly be aesthetically pleasing, but those and the vast majority of other machined metal parts serve a practical function first and foremost. The metal parts Chris Bathgate machines don’t.

01/28/2019

Almost every machine shop uses facemills for roughing, semifinishing and finishing, but many of these shops miss out on increased material-removal rates because they run yesterday’s tooling on today’s machine tools. The larger spindle tapers and higher horsepower ratings, feeds and speeds of modern machines need to run with the latest in facemilling cutter and insert technology to maximize a machine’s facemilling potential and thus significantly speed up production, increase efficiency and reduce cost per part, especially on larger workpieces.

01/25/2019

Expand existing capacity or turn down orders? Many companies are caught in this dilemma. Every time a company turns down an order, it risks losing that customer and potential orders. If the company has no alternative but to accept new orders, at some point the existing machines will reach their limits. What then?

01/24/2019

Whether they’re required for downstream manufacturing steps or for error-free functioning, surface characteristics are decisive with regard to part and product quality. Processes such as deburring and precision surface finishing are becoming more and more significant as a result – regardless of whether the parts are produced by means of erosion, forming, primary forming or additive manufacturing. DeburringEXPO, the world’s only trade fair that deals exclusively with the removal of burrs and the production of precision surface finishes, will be held at the Karlsruhe Exhibition Centre from Oct. 8-10, 2019.

01/22/2019

CNC machining is one of the most common methods used to manufacture parts and products. The use of computer numerical controls allows parts to be manufactured using a highly automated process, which has the upper hand on many conventional manufacturing methods in terms of speed, production rate and accuracy. However, determining the right material for the process can be a daunting task.

01/22/2019

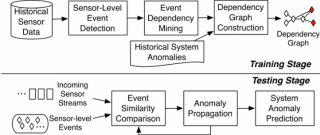

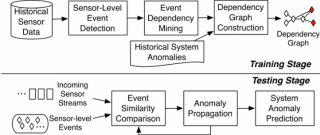

It is time to put smarter manufacturing into production. An increase in the data and sensors available to the manufacturing industry has made it much easier to gather data on manufacturing efficiency through the internet of things. However, IoT systems tend to look at sensors at an individual level, which limits the ability to forecast anomalies across a manufacturing operation, as each sensor can measure only a specific part of the operation. To address this issue, a team of researchers has created a framework for system-level anomaly prediction in manufacturing.

01/22/2019

As the aerospace industry in Canada and around the world continues to increase its use of automated composite manufacturing techniques to produce large aircraft components, the industry is eager to find solutions to manufacture reliable, safe, and cost effective composite structures. The National Research Council of Canada (NRC) and Fives are working together to improve the efficiency of manufacturing composite parts. They are developing an advanced profilometer that will provide faster and more accurate part inspection.