Increasing production capacity, the right way

Increasing production capacity, the right way

Expand existing capacity or turn down orders? Many companies are caught in this dilemma. Every time a company turns down an order, it risks losing that customer and potential orders. If the company has no alternative but to accept new orders, at some point the existing machines will reach their limits. What then?

Article from Hoffmann Group

Expand existing capacity or turn down orders? Many companies are caught in this dilemma. Every time a company turns down an order, it risks losing that customer and potential orders. If the company has no alternative but to accept new orders, at some point the existing machines will reach their limits. What then?

Is it justifiable to procure an additional machine when it is uncertain how long the surge in orders will last? Is the time lag of several months between ordering and receiving a new machine worth it? Many production managers suffer sleepless nights wrestling with such questions. A new machine represents a substantial investment, often a seven-figure sum. It also needs space, personnel to operate it and is not immediately ready for use.

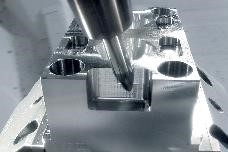

Alternatives with a relatively small investment and no loss of time that can achieve significantly more from existing productive resources are therefore very attractive. Parabolic performance cutting (PPC) milling is one such technique. Koller Formenbau GmbH of Dietfurt in Altmühltal, Germany, has had great success using PPC milling cutters supplied by the Hoffmann Group to reduce the finish machining time for geometrically defined surfaces from 100 hours to 15 hours.

Koller Formenbau in China. Future GARANT PPC barrel milling cutters will also be used in the new factory in Nanjing.

Massive Reductions in Finish Machining Time

PPC is also called barrel milling. Like that of a ballnose endmill, the main cutting edge of a PPC milling cutter is curved as an arc of a larger radius circle. While the effective radius for a classic ballnose endmill is only half the diameter, a PPC milling cutter has a much greater effective radius. This allows a significantly greater engagement length on the workpiece. A barrel milling cutter also achieves a step-over up to nine times greater than that of a ballnose endmill of equivalent diameter, thus placing less stress on both the tool and the workpiece. If the same step-over is maintained, a surface quality up to 80 times better can be achieved.

The Hoffmann Group offers a variety of tools with effective radii up to 1000 mm. Eventually, larger radii could be implemented in tools, but the long engagement length would demand high contact pressures. The resulting displacement of the tool would have a negative effect on precision, something that cannot be compromised. The Hoffmann Group also offers special solutions with effective radii different from those in the catalog. This allows the customer to gain the optimal benefits from PPC for specific applications. To fully take advantage of PPC, a radius in the range of 700 or 800 mm is optimal.

Parabolic performance cutting with a larger effective radius achieves better surfaces in a shorter time with less stress on the tool and the workpiece.

Different Profiles and Approach Angles

PPC is particularly effective when the tool profile is suitable for the workpiece surface contour (5-axis machining). Depending on the application, up to four different tool profiles are necessary for optimal machining of workpieces and free-form surfaces with highly complex surface geometries. Surfaces with interference contours, large areas, deep cavities or flat faces each demand different tool profiles.

The Hoffmann Group offers a variety of cutting edge profiles: straight, tangential, conical and stub point conical. Each represent a specialized solution for machining different types of surfaces. For all profiles, the tool is mounted at an oblique angle. The Hoffmann Group also offers three different approach angles for the conical and stub point conical PPC milling cutters. These allow the operator to use the optimum type of milling cutter for each specific application. These tools provide precision, such as a steeper approach angle that allows interference contours to be avoided.

With an effective radius of up to 1000 mm, PPC milling cutters have a significantly larger engagement area than ballnose endmills.

CAD/CAM with Tooling Database

In contrast to ballnose endmill cutting, PPC is more dependent on software. Classic ballnose endmill cutting only requires a small amount of information to calculate an appropriate milling strategy using the CAM software. It shows tool diameter, length and which tool is most useful. The more complex tool profiles of PPC can be calculated in combination with CAM software that offers barrel milling as a strategic option. Additionally, the software has a tool database which holds the exact geometries of the PPC milling cutters.

Because of their special free-cutting qualities, GARANT PPC milling cutters for aluminum can also be used for machining plastics.

Because PPC tools are aligned obliquely to the workpiece, it can only be used in conjunction with a 5-axis milling machines. As 5-axis machines become increasingly more useful, so does PPC milling. It is not always necessary to control all five axes simultaneously. Often, once the tool has been set up, the draft angles can be machined with one or two axes clamped in order to achieve better results. At one time there were only a few software programs that offered a "barrel milling" functionality, but that has changed in recent years. Koller Formenbau already had a 5-axis machine in use that operated on Hypermill software, and only then did it seek suitable barrel milling cutters. At a moderate expense, the company has been able to achieve up to 85 percent gains in productivity, thereby significantly increasing the productive capacity without having to purchase new machine tools.

The selected approach angle also makes a difference. Therefore, the Hoffmann Group offers conical and stub-point conical PPC milling cutters with three different approach angles.

Increasing Areas of Application

A classic area of application for PPC is finish machining of complex components and free-form surfaces in machine tool manufacture and in mold and die production. PPC is also attracting increasing interest in medical, turbine and aerospace technology. A relatively new area of application is the finish machining of workpieces produced by additive manufacturing, permits particularly complex workpieces to be produced in a single production operation. However, workpieces produced on a 3D printer fall short of the surface quality required for contact faces. Such workpieces must be finish machined. PPC was conceived for exactly such applications. Because a variety of different materials are often used for the 3D printing process, the Hoffmann Group has extended its PPC milling cutter family to cater to a wide range of materials.

For machining of surfaces with highly complex geometries up to four different tool profiles can be necessary.

PPC milling cutters for machining aluminum were demonstrated for the first time at AMB 2018. The new milling cutters are particularly sharp-edged and can also be used for machining plastics. This significantly extends the existing portfolio over a wide range of applications.

Companies that invest in alternate paths such as CAM-controlled PPC can achieve substantial increases in productivity at a relatively low cost and without having to add new machines. No longer do companies or customers have to compromise on efficiency at the expense of productivity.