Industry News

05/06/2024

Okuma America Corp., has named new personnel appointments to "direct and support" the company's strategic growth initiatives in the Americas.

05/03/2024

In a highly anticipated return to Chicago this spring after a five-year hiatus, Automate—the largest robotics and automation trade show in North America—will set new show records for number of attendees and exhibitors.

05/02/2024

In a move to strengthen its floor grinding & surface preparation business, the Tyrolit Group invests in German company Contec Maschinenbau & Entwicklungstechnik GmbH. Contec is a leading global supplier of state-of-the-art machines for surface preparation and finishing.

05/01/2024

GF Machining Solutions has promoted Onik Bhattacharyya to the position of managing director and head of market region for North and Central Americas.

04/30/2024

Walter is bringing together its global presence and the high level technical expertise and know-how of lightweight machining specialist FMT (Frezite Metal Tooling), under the new brand.

04/29/2024

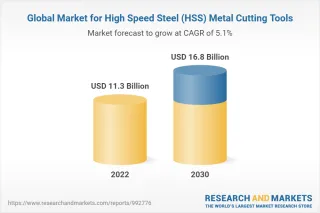

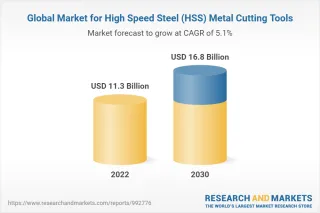

The global market for high speed steel (HSS) metal-cutting tools estimated at $11.3 billion in the year 2022, is projected to reach a revised size of $16.8 billion by 2030, growing at a CAGR of 5.1% over the analysis period 2022-2030.

04/26/2024

Purchase of Ontario-based Canadian company supports the growth of MSC’s Metalworking presence in Canada.

04/25/2024

Swedish startup PaperShell has developed a cellulose fiber composite that they refer to as “wood metal” and it can be formed into flat or complex-shaped components.

04/24/2024

HGG Profiling Equipment BV has named Mark Eastin as the area sales manager in the Western US, Western Canada, Alaska, and Hawaii regions.

04/23/2024

SMW Autoblok Group, a leader in the design and manufacture of rotational chucks, stationary workholding, tooling, automation, and custom engineered solutions for the machine tool industry, has appointed Larry Robbins as the company’s new President and CEO of their U.S, corporation

04/22/2024

The Tyrolit Group said it is expanding its production site in Stans, Austria, and investing 15 million euros in a new, highly innovative production line.

04/19/2024

Cutting tool supplier Sandvik Coromant hosted a Girls Take Over Tech open house to “inspire and educate young women and girls about exciting career opportunities in manufacturing.”

04/18/2024

General Carbide Corporation, in partnership with Westmoreland County Forum for Workforce Development; held an exclusive student tour at its state-of-the-art manufacturing facility.

04/17/2024

Genuine Parts Company, a distributor of automotive and industrial replacement parts, has appointed James F. Howe to the position of President, Motion, the company's industrial business, effective April 1, 2024.

04/16/2024

Shelton Machinery has acquired Municipal Tool & Machinery, and launched a new parent company called TSM Group. TSM is the new parent of Shelton Machinery, Concept Machinery and Municipal Machinery.

04/15/2024

Sandvik has signed an agreement to acquire Almü Präzisions-Werkzeug GmbH (Almü), a Germany-based cutting tools and solutions provider within high-precision drilling, reaming, milling and tooling systems.

04/12/2024

Concepts NREC, a leading provider of turbomachinery solutions, announced that it has been named one of the Best Places to Work in Vermont

04/11/2024

WALTER Surface Technologies is pleased to announce the acquisition of PushCorp, Inc., a USA-based, industry-leading manufacturer of robotic end-of-arm-tools for material removal applications.

04/10/2024

Kennametal Inc. announced that Katie Myers, product manager, marketing, and Zhuqing Wang, staff engineer, materials science have been recognized as a 2024 Emerging Leader and Women MAKE Award Honoree respectively by The Manufacturing Institute.

04/09/2024

Metrology has always been vital in precision manufacturing to ensure products meet quality and design specifications, according to Paul Maxted, director of Industrial Metrology Applications at Renishaw, in his whitepaper "The changing face of metrology."