Industry News

10/09/2017

Most inspection-in-manufacturing features these days are about precision metrology equipment. This one is about people. More frequent rotation of (human) plant inspectors at medical device manufacturing facilities could benefit consumers and lead to fewer product recalls. That's the finding of a seven-year review of Food and Drug Administration inspections of and subsequent recalls at such facilities.

10/09/2017

Vero Software Ltd., Cheltenham, England, hired Bill Horvat as outside sales account manager based in Delavan, Wis., to represent the Surfcam and Edgecam brands.

10/09/2017

Hexagon AB, Surrey, U.K., a provider of information technologies that drive productivity and quality across geospatial and industrial enterprise applications, acquired assets from Kronion GmbH, Landau, Germany, and transferred them to Hexagon Manufacturing Intelligence, North Kingstown, R.I.

10/09/2017

Benz Inc., Hickory, N.C., which produces CNC tooling for the metal, wood and composites industries, named Brian Krin the Southeast regional sales manager for metal tooling.

10/06/2017

Vero Software Ltd., Cheltenham, England, appointed Hector Henry brand manager of its Alphacam CAD/CAM solution.

10/06/2017

Over 2,000 toolholders from Lyndex-Nikken Inc., Mundelein, Ill., are now available through MachiningCloud Inc., Camarillo, Calif.

10/06/2017

Mitutoyo America Corp., Aurora, Ill., provided Digimatic calipers and micrometers to students pursuing degrees in the engineering technology program at Northern Illinois University.

10/06/2017

In line with its strategy to digitalize its offering, GF Machining Solutions LLC, Lincolnshire, Ill., agreed to purchase 100 percent of the shares of Symmedia GmbH, Bielefeld, Germany.

10/05/2017

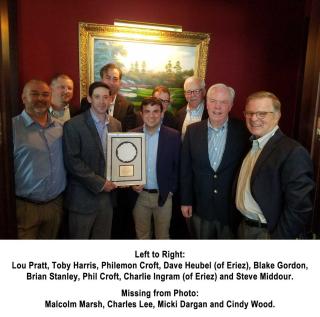

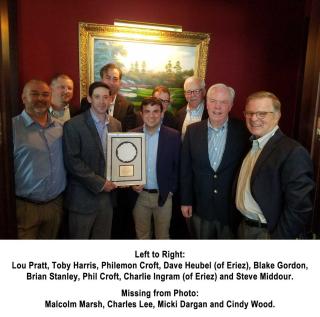

Charlie Ingram, vice president of sales and marketing at Eriez Manufacturing Co., Erie, Pa., announced Adams Brothers Inc., Atlanta, as the winner of the 2016 Merwin Sales Award.

10/05/2017

Jergens Inc., Cleveland, and MachiningCloud Inc., Camarillo, Calif., partnered to provide Jergens product data in the cloud.

10/05/2017

Radix Inc., Windsor, Ontario, acquired vision system integrator Automated Detection Devices Inc., Mississauga, Ontario.

10/05/2017

Cutting tool manufacturer Walter USA LLC, Waukesha, Wis., appointed Dan Shelton managing director of the U.S.

10/05/2017

Easy, accurate tracking of items through the manufacturing process is becoming more and more important in the quality-conscious 'Smart-Factory' era. RFID tagging has distinct advantages as a tracking method, but barcode scanning has its adherents too.

10/04/2017

MC Machinery Systems Inc. hosted more than 1,000 customers, visitors and team members for the grand opening of its new headquarters in September. The event was one of the first opportunities for customers and partners to explore the 175,000-sq.-ft. facility, which includes a 50,000-sq.-ft. showroom among many other modern amenities.

10/04/2017

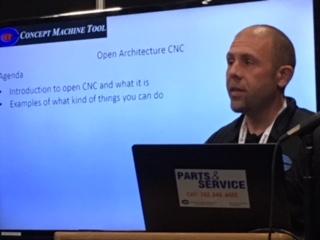

For those who want to enhance a CNC by adding capabilities, Chris Robson, applications engineer for Minneapolis-headquartered machine tool dealer Concept Machine Tool – (Delafield) Wisconsin, gave a presentation titled “What Else is Inside this Box? Open Architecture CNC.” His seminar took place Oct. 3 at the 15th biennial Wisconsin Manufacturing & Technology Show in the Exhibition Center at the Wisconsin State Fair Park, Milwaukee.

10/03/2017

"Both are used to achieve a smooth surface and precision dimensions on metal parts," writes MC's Joshua Jablons. "Both are usually performed at the end of the manufacturing process to remove a very small amount of material or finesse the finish on a part. The difference between honing and lapping begins to be revealed if we look at where on a part each process is performed: While honing is used where parts need a precise inside diameter, lapping is performed on an outside flat surface. And when we look at what each process is, the distinctions between the two are plain to see."

10/02/2017

LiquidPlanner Inc., Seattle, a developer of dynamic project management software, and P3 Group, Aachen, Germany, a manufacturing consultancy, partnered to deliver project management software and accelerate deployments for manufacturing customers worldwide.

10/02/2017

Dürr Ecoclean GmbH, Filderstadt, Germany, is changing its name to Ecoclean.

10/02/2017

Jet Tool & Cutter launched in 1968 as a small cutter regrind shop, taking orders on paper and mailing quotes back to the customer. Since then, the bustling, growing firm has worked out the solution that allows it to quickly produce a wide variety of high-quality carbide cutting tools for aerospace, firearms and general machining applications. Its solution allows the shop to meet tightening customer demands for quality and quick delivery while facing a shrinking pool of available skilled hands.

10/02/2017

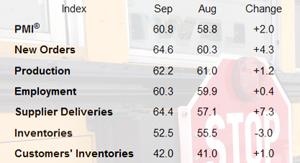

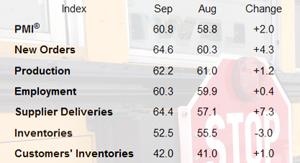

Economic activity in the manufacturing sector expanded in September, and the overall economy grew for the 100th consecutive month, say the nation's supply executives in the latest Manufacturing ISM Report On Business. The September PMI was 60.8 percent, an increase of 2 percentage points from the August reading of 58.8 percent. This indicates growth in manufacturing for the 13th consecutive month and is the highest reading since May 2004, when the index registered 61.4 percent.