Industry News

09/29/2017

Almost 30,000 metric tools from Komet Group GmbH, Besigheim, Germany, are now available through MachiningCloud Inc., Camarillo, Calif.

09/29/2017

In manufacturing, the nature of the work as well as the nature of the workers are changing: What’s a prospective employer to do? Some pre-Manufacturing Day discussion.

09/28/2017

Advances in technology and changing trade patterns are affecting opportunities for export-led manufacturing. Smart automation, advanced robotics and 3-D printing are new factors influencing which locations are attractive for production. While these shifts threaten significant disruptions in future employment, particularly for low-skilled workers, they also offer opportunities, according to a new report released today by the World Bank Group.

09/28/2017

If you’re lucky, the veterans in your shop will take a rookie aside and pass on their hard-won knowledge of good machining practices. Most of this information is priceless. But some of it … not so much. For example, there are a lot of myths about balancing out there that, if not refuted, can cost your operation a lot of lost time and money. In this article, Haimer USA LLC addresses these misperceptions and offers a more factual view of best practices for balancing toolholder assemblies.

09/28/2017

Entering the workpiece is an essential part of optimizing tool life and reducing vibrations. The roll-in method allows you to softly and smoothly enter the workpiece. Inserts are eased into the cut following the golden rule of milling: a thick chip on entry and a thin chip on exit. Click on the link for more milling tips from Sandvik Coromant.

09/28/2017

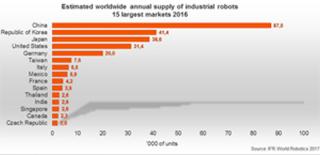

In 2017 robot supplies in the Americas will surge by 16 percent from 2016, according to the International Federation of Robotics. IFR estimates that by 2020 the worldwide stock of operational industrial robots will increase from about 1,828,000 units at the end of 2016 to 3,053,000 units—an average annual growth rate of 14 percent between 2018 and 2020.

09/28/2017

A new report from Kaspersky Lab found that in the first half of the year, the manufacturing industry was the most susceptible to cyberthreats – with the industrial control systems (ICS) computers of manufacturing companies accounting for almost one third of all attacks.

09/27/2017

Absolute Machine Tools Inc., Lorain, Ohio, hired Jeff Sturtevant as general manager of the Mason Technical Center in Mason, Ohio.

09/27/2017

Join thousands of manufacturers Oct. 6 as they open their doors to show modern manufacturing in action and inspire the next generation of skilled workers. Manufacturing Day is an annual celebration in which manufacturers invite their communities—including students, educators, businesspeople, media and politicians—to facilities in a collective effort to educate visitors about manufacturing career opportunities and improve public perceptions of manufacturing.

09/27/2017

If you have ever had parts or components CNC milled, you probably have a good understanding of the process. However, unless you have had custom products manufactured, you may not be aware of everything that goes hand-in-hand with custom CNC milling.

09/27/2017

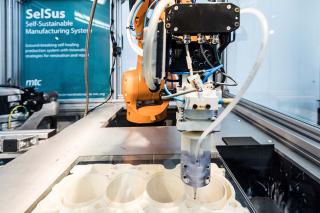

In the EU-funded project SelSus, Fraunhofer scientists are collaborating in a consortium with partners from research and industry to develop maintenance technology capable of forecasting machine downtimes in production before they occur. This allows plant managers to rectify faults before the machine breaks down. The system even corrects some defects automatically.

09/27/2017

Although picks, or plectra, for playing musical instruments are commonly plastic injection molded or stamped, some are machined.

09/26/2017

Precision Drive Systems LLC, Bessemer City, N.C., a global provider of high-speed precision spindle motors, support and repair, named Bob Barone vice president.

09/26/2017

Cutting Tool Engineering (CTE) is seeking machine shop candidates to be featured in an episode of our new Shop Ingenuity video series, which debuted earlier this year. The series is open to any shop that would like to share its story of shop innovation.

09/26/2017

Coldwater Machine Co., Coldwater, Ohio, an engineered solutions and precision machining company that manufactures and integrates assembly automation and special machines, announced a 27,500-sq.-ft. expansion to its manufacturing space, enlarging the facility to 132,500 sq. ft.

09/25/2017

Fairmont Supply, Washington, Pa., which distributes industrial maintenance, repair and operation supplies in the United States, appointed Paul Fichiera CEO.

09/25/2017

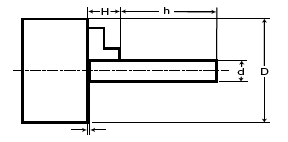

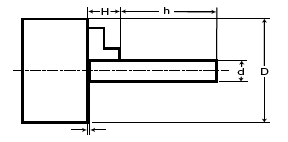

Top jaws should be designed to hold the workpiece as close to the chuck face as possible. Excessive jaw height reduces the effective gripping force available and is detrimental to accuracy.

09/22/2017

GF Machining Solutions LLC, Lincolnshire, Ill., named Ellison Technologies Inc., Los Angeles, as its distributor to serve customers in Indiana.

09/22/2017

Engineers at NASA's Marshall Space Flight Center in Huntsville, Alabama, tested NASA's first 3-D printed rocket engine prototype part made of two different metal alloys through an innovative advanced manufacturing process. NASA has been making and evaluating durable 3-D printed rocket parts made of one metal, but the technique of 3-D printing with more than one metal is more difficult.

09/22/2017

Premier Industries’ pressure regulators are subjected to tough duty in the oil & gas, aerospace and welding industries, but their precision performance is also critical, as regulator outlet pressure determines downstream pressure. A HORN modular toolholding system allow the company to reduce cycle times by 65 percent and cost per part by 79 percent—with better finish, flatness and tool life.