Industry News

03/10/2021

ARCH Cutting Tools has named Doug Wickham as its new direct marketing/business analyst. In this role, he is working with the Bloomfield Hills, Michigan-based ARCH Cutting Tools marketing and business development team and reports to Stacey Eeman, marketing and business development manager.

03/09/2021

Eriez, a supplier of separation technologies, expanded its Wager Road manufacturing and testing facility that will support Eriez’ strategic growth initiatives for global research and development, aftermarket repair and testing, and recycling equipment technology.

03/08/2021

Customers of Big Kaiser helped raise $6,275 to benefit the National Robotics League (NRL). This represents the fifth annual contribution to the program by the Hoffman Estates, Illinois-based company.

03/05/2021

Tormach Inc., a Waunakee, Wisconsin-based supplier of compact CNC machines, named Darcy Johnson as its chief financial officer (CFO).

03/04/2021

New CAM software from Mastercam in Tolland, Connecticut, is now available for a public beta testing.

03/02/2021

Greenleaf Corp. in Saegertown, Pennsylvania, released the XSYTIN-360, a new line of high-performance solid ceramic end mills, to the global market.

03/02/2021

John Blicha has been named global senior director of marketing and brand management for Eriez. Blicha joined Eriez in 2012 as manager of marketing communications.

03/01/2021

The Coalition of American Metal Manufacturers and Users (CAMMU) sent a letter to President Joe Biden requesting the immediate termination of the Section 232 tariffs on steel and aluminum imports enacted under the Trump administration.

02/26/2021

The National Institute of Metalworking Skills (NIMS) is partnering with Edge Factor, an online learning company, to inspire students and job-seekers to pursue career pathways in manufacturing and other skilled trades.

02/25/2021

Andretti Autosport announced that Applied Automation Technologies will serve as the team’s official metrology solution.

02/24/2021

Robot density in manufacturing hit a new global record of 113 units per 10,000 employees.

02/23/2021

Shawn Lawlor has been named CEO of DAPRA after Linda Pilvelis retires March 1, 2021.

02/22/2021

In the past decade, a California-based machine shop has relied on a flexible, honing tool for a range of automated CNC machining applications such as cross hole deburring, cylindrical honing, surface finishing, edge-blending and cleaning.

02/18/2021

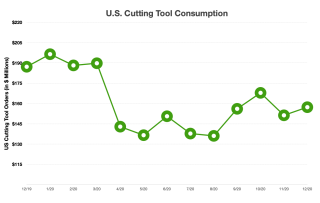

The U.S. manufacturing industry continued to rebound in December 2020 with cutting tool consumption up 4% over November and the Manufacturing Purchasing Manager's Index expanding from 57.5 in November to 60.5 in December.

02/18/2021

Using a Vicivision optical measuring machine to verify quality during grinding and other operations, Italy-based Bavieri Alfeo Precision Mechanics can obtain accurate results in seconds .

02/17/2021

Precision aerospace part manufacturer Alloy Specialties is one of the first adopters of a new robotic quality inspection technology, Tempo, from Hexagon’s Manufacturing Intelligence division.

02/16/2021

Allied Machine & Engineering launched Allied Tool Academy, which is an online training program.

02/12/2021

CRP Meccanica an equipment distributor in Modena, Italy, signed an agreement with VELO3D to be an exclusive distributor for VELO3D’s advanced Supportfree Metal 3D printing systems in the Italian market.

02/12/2021

Voestalpine Rotec GmbH, a global leader in the manufacture of precision steel pipes and tubes, integrated an automated Rösler drag finishing system, the R 4/700 SF, that doubled the usable life of stamping tools.

02/11/2021

After a long hiatus due to the COVID-19 pandemic, the Grinding Doc video series on Cutting Tool Engineering's website resumes with a special two-hour episode about Cylindrical Master 2020, an Excel program developed by Dr. Jeffrey Badger, aka the Grinding Doc. The 105th episode of the Grinding Doc video series provides a detailed description of the Cylindrical Master program that Badger developed during the pandemic.