Industry News

09/29/2020

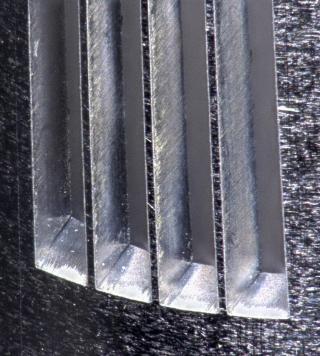

Laser technology was developed in the mid-20th century, and over the decades has emerged as a leading processing method for a broad range of applications. One of the newest uses is for high precision laser micromachining.

09/28/2020

The metal machining, fabrciation and finishing industries must meet EPA and local wastewater requirements for effluent. Under the Clean Water Act, the EPA has identified 65 pollutants and classes of pollutants as “toxic pollutants,” of which 126 specific substances have been designated “priority” toxic pollutants. Failing to meet these requirements can result in severe fines that quickly escalate.

09/28/2020

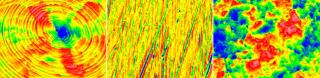

To contact or not to contact. That is the measurement question. Today, as parts get smaller and more complex, metrology discussions center around contact or non-contact measurement especially as these smaller and more complex components can be damaged by contact with a probe.

09/25/2020

Schunk, a premium tooling and resharpening company in Germany, utilizes state-of-the-art grinding systems and an ANCA workflow RFID system to finish job packets in a chaotic fashion driven by production needs rather than by job order.

09/25/2020

The US cutting tool manufacturer McQuade Industries Inc. has implemented a CNC upgrade program for its roster of 5-axis insert grinders, and the upgrades shaved more than ten minutes per part off the production time of complex geometry cutting tools.

09/24/2020

Registration is now open for Ceratizit’s virtual event that runs from Sept. 30 to Oct. 30, 2020.

09/24/2020

Submarine propellers traditionally take a long time to produce. They are large and have tight tolerances. A Starrag machining center was selecting to produce the 24' propellers.

09/23/2020

Seco Tools LLC has named Brad Andrews has joined Seco North America as Regional Manager – Canada. Brad is responsible for leading the Canadian team and developing and implementing the North America sales strategy to drive growth.

09/23/2020

The larger the series of parts to be produced, the more important cycle times and tool costs are. Designing machinery and tooling through a collaborative design process reduces cycle times and tooling costs, while improving part quality.

09/22/2020

IMCO Carbide Tool Inc., an Ohio-based tool manufacturer, has joined the IMC Group, an international family of metalworking companies that is part of Berkshire Hathaway Inc. conglomerate.

09/21/2020

The Australian Government has ordered the construction of a fleet of 12 regionally superior submarines, known as the Attack Class, for the Royal Australian Navy. A 5-axis gantry machine from The Starrag Group is a critical piece of equipment for the decades-long project.

09/18/2020

The Integrex i-H series of multi-tasking machines from Mazak was designed to allow for additional automation technologies to be added onto the machine after purchase as a company's production needs grow and change.

09/16/2020

Reducing the environmental footprint in a production plant is often achieved with state-of-the-art production equipment, but many companies are looking to improve on these achievements.Oil filtration might be a good way to help improve the environment.

09/15/2020

Kratzer GmbH & Co. is a Offenburg, Germany-based precision manufacturer of components made from a wide range of materials that must meet the exacting standards required by its high-tech cuustomers. The company meets these specifications in part through investing in state-of-the-art equipment including grinding machines, machining centers, lathes, metrology equipment. Recently, the company invested in new grinding technology as well as a new filtration system.

09/10/2020

A Russian battery maker was looking to automate its manufacturing process and turned to Wenaroll in Solingen, Germany, experts in burnishing technology, to develop a turnkey production system.

09/09/2020

Chicago Jet Group retrofitting a Dassault Falcons plane turned to a leading metrology provider for help in recreating a replica of a cockpit panel to ensure it would fit snugly in the cockpit..

09/08/2020

A Chicago family dynasty ended July 8, 2020, with the passing of Tom Breitenstein, who, like his father, enjoyed a long and fruitful career in the machine tool industry.

09/03/2020

Tooling manufacturers must machine tools to cut an evolving array of materials from exotic metals to composites and meet ever-more exacting tolerances and produce more complex shapes and radii.

09/02/2020

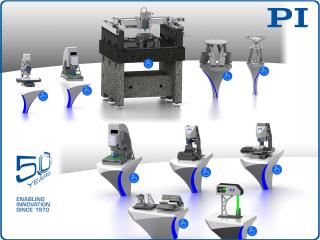

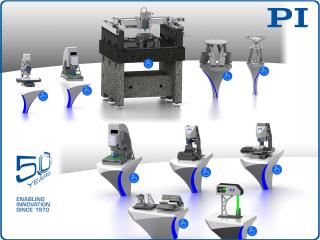

PI (Physik Instrumente) LP, a provider of motion control and laser processing solutions, launched a virtual tradeshow on its website. The tradeshow features industrial automation and laser material processing products.

08/25/2020

From September to November, optical measurement supplier Bruker Alicona is hosting a U.S. roadshow. In more than 20 cities, exclusive demos of their optical metrology equipment will be organized under consideration of COVID regulations.