According to Thompson Reuters news, as of March 2011, 69,000 bridges in the U.S. were in need of maintenance or replacement. Exhibiting the tools and the talent in which other fabricators reportedly do not, LeJeune Steel Co. of Minneapolis, specializes in bridge fabrication using Peddinghaus equipment. Lejeune, together with their heavy fabrication division, Wisconsin Structural Steel are prime examples of what modern technology and traditional craftsmanship can do in today's economy.

Responding to the need for quality public transportation, the University of Minnesota called upon LeJeune to introduce a new light rail train system. This system is to be incorporated into one of the university's most recognizable landmarks, the Washington Avenue Bridge. As a prerequisite for the installation of the light rail, this nearly 50 year old bridge had to be reinforced to support the extreme weight of the new trains along with existing traffic above. The bridge enhancement spans just less than ¼ mile, and demands 240 heavy steel box sections at 25' (8m) and 50' (15m) long increments to properly support the weight of the new train system.

LeJeune's counterpart Wisconsin Structural, relies Peddinghaus equipment to process the heavy sections needed. Each of the 16,000lb (7,250kg) box sections for the bridge are being processed on a Peddinghaus BDL-1250/9B drill line. The BDL-1250/9B drill line, in tandem with DGP-1270 automatic band saw proves to be a prevailing combination when accuracy is a major concern. Precision in bridge projects are regulated and must meet the highest of standards.

"Our Peddinghaus equipment is extremely accurate," Brad Fox, Plant Manager at Wisconsin Structural Steel said. "The box sections for the bridge in Minnesota are expensive to produce, so any error would cause a major cost issue. So far the machine has consistently drilled well within tolerances of 1mm. We like to do things right the first time, and we are able to do that with the Peddinghaus machines that we have."

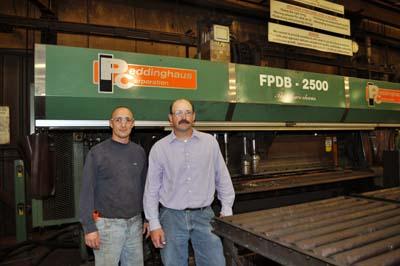

The Peddinghaus FPDB plate processor is also an effective tool for parts requiring high accuracy, and rapid production times. High speed carbide drilling combined with the carbide marking capabilities of this workhorse provide superior production, without sacrificing quality or material handling efficiencies. LeJeune Steel uses this machine for many of their bridge projects. After parts are completed at Wisconsin Structural, they are sent to LeJeune for final quality control inspection. LeJeune also fabricates several bridges and structures in the area using Peddinghaus equipment.

"You will see multiple bridges at any given point in time at our Minneapolis plant," Matt Rovnak, Business Manager at LeJeune Steel, stated. "So far, every part from our Peddinghaus machines has been right on the money!"

Contact Details

Related Glossary Terms

- bandsaw blade ( band)

bandsaw blade ( band)

Endless band, normally with serrated teeth, that serves as the cutting tool for cutoff or contour band machines.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.

- sawing machine ( saw)

sawing machine ( saw)

Machine designed to use a serrated-tooth blade to cut metal or other material. Comes in a wide variety of styles but takes one of four basic forms: hacksaw (a simple, rugged machine that uses a reciprocating motion to part metal or other material); cold or circular saw (powers a circular blade that cuts structural materials); bandsaw (runs an endless band; the two basic types are cutoff and contour band machines, which cut intricate contours and shapes); and abrasive cutoff saw (similar in appearance to the cold saw, but uses an abrasive disc that rotates at high speeds rather than a blade with serrated teeth).