The latest release of the game-changing Alphacam CAD/CAM software from Vero ensures that users can exploit the full power of their PC. Alphacam 2015 R2 is 64-bit compatible, meaning its programs can utilize all available memory.

"With 32-bit computers only able to work with 2GB, irrespective of how much memory is onboard, some large files are extremely difficult to work with," says Alphacam Technical Manager Paul Green. "We gave a high priority to this development, as it means end users can now process large files without any issues arising."

Amongst the full array of new and enhanced functionality in Alphacam 2015 R2:

The GUI includes a new fully customisable radial menu. It means users can set up as few or as many commands as they need, according to the company.

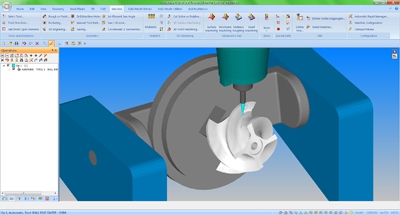

For Advanced 5-Axis Machining, while the previous release of Alphacam introduced surface machining, considerable enhancements in 2015 R2 give many more advanced options, including wire frame machining for effective trimming, and multi-axis roughing which allows roughing to the actual contour, removing any unnecessary fresh-air machining. Side Wall Axial Relief Feed (SWARF) machining reduces 5-axis cycle times and gives a better surface finish through effective side-of-tool machining. The strategy is to finish the part in one cut, through constant cutting conditions giving increased material removal and a constant low cutting force, along with simultaneous 5-axis vector orientation providing full access to machining areas.

Enhanced Feature Extraction makes it easier to find features on orthogonal panel faces. There is now the option of finding holes and contours on any panel face at the same time, speeding up panel processing.

Another major aspect of new functionality has been added to Part Management, with full associativity between a part and its copy. Whenever an original part is amended on Alphacam 2015 R2, there is the option to automatically update the copy.

Improved on-screen realism is achieved through Rendered Z-Level Geometries and Material Textures. "By rendering Z-level parts we're making them visually clearer to the user," says Paul Green. "And users can now apply any texture, whether it be metal, wood, granite, plastic or composite, so that it looks on-screen how it will look on the machine. Rendered clamps and fixtures can also be shown on a full machine configuration."

A command in the Rough Finish cycle – Previous Tool Profile – automatically uses the profile of the previous tool to generate the new tool path to machine corners where form and shaped tools have left material there.

A new function in Nesting now identifies parts by name, rather than number as in previous releases. As well as the part names showing in the nest on-screen, they also appear in reports. It helps to make in formation more relevant – users can see at a glance which part is on a nested sheet.

Solidworks Assembly Support considerably speeds up processing. While Alphacam has been able to import Solidworks files of individual parts for many years, one click now brings in a full assembly file containing all the parts.

Subtle changes to Part Modeler give higher quality image previews, along with commands for part manipulation including rotation around a specific point or axes, and zoom to a cursor.

Contact Details

Related Glossary Terms

- cutting force

cutting force

Engagement of a tool’s cutting edge with a workpiece generates a cutting force. Such a cutting force combines tangential, feed and radial forces, which can be measured by a dynamometer. Of the three cutting force components, tangential force is the greatest. Tangential force generates torque and accounts for more than 95 percent of the machining power. See dynamometer.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- relief

relief

Space provided behind the cutting edges to prevent rubbing. Sometimes called primary relief. Secondary relief provides additional space behind primary relief. Relief on end teeth is axial relief; relief on side teeth is peripheral relief.