A technique I call roll grinding is used to finish corners to match bend radii. Long weld seams that need to be rounded can be handled using a rolling technique with the disc grinder. It takes a little practice, but once you’ve mastered it, the results look just like a formed corner.

In one shop I worked at, we roll-ground miles of seams. Good welding technique can minimize the amount of metal removal in this finishing method.

All images courtesy T. Lipton

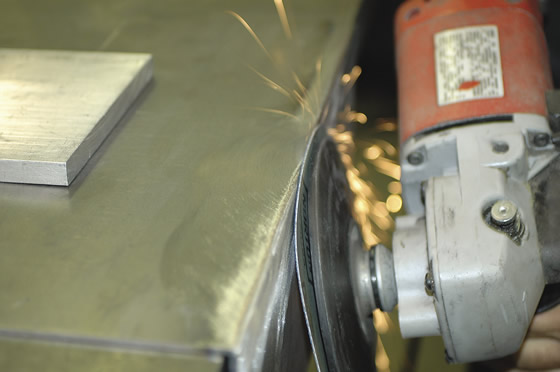

When roll grinding, first deck off the weld flush against two intersecting right-angle surfaces.

The weld should first be decked off flush against the two intersecting right-angle surfaces. For bumpy welds, I sometimes take a few light faceting passes to even everything out.

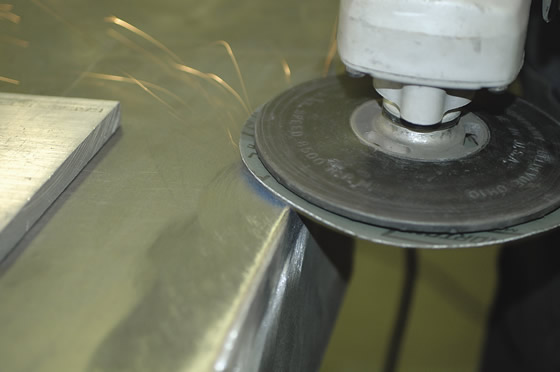

If you’re right-handed, stand with the weld to your right. Your right hand is the balance hand that supports the weight of the grinder while your left hand does the precision rolling motion. The wheel, or disc, should be kept as flat as possible on the weld seam. Very little pressure is needed to do the actual rounding. Think of your right hand as the pivot holding a round object, like a motorcycle grip or a piece of round handrail. As you sand, step slowly backward along the seam.

For bumpy welds, take a few light faceting passes to even everything out before roll grinding.

The rolling passes should overlap by three-quarters of the disc diameter or more.

For right-handed people, the rolling action should be applied with the left hand and should go flat to flat through 90° or a little less.

Your rolling passes should overlap by 75 percent or more of the disc diameter. Remember, this is not an aggressive action, but a fine finishing one. The rolling action with the left hand should go flat to flat through 90° or just a little shy. If you do everything correctly, the results should look almost exactly like a formed bend produced on a brake.

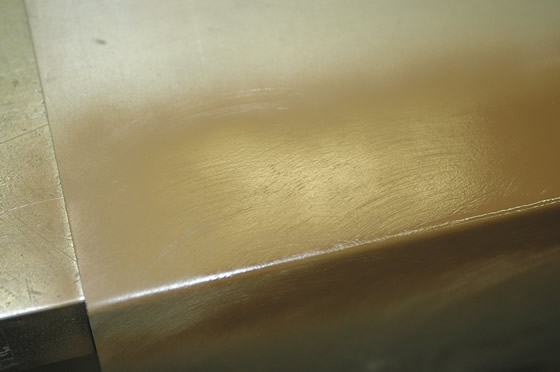

When finishing corners, the myth that paint will fill in the scratches on the finished part continues to survive. The best way to describe why it doesn’t work is to look at some snow-capped mountain peaks. Even if a little snow is on the mountain, you can still see the mountain. Similarly, parts show grinding scratches even after a light coat of flat paint is applied.

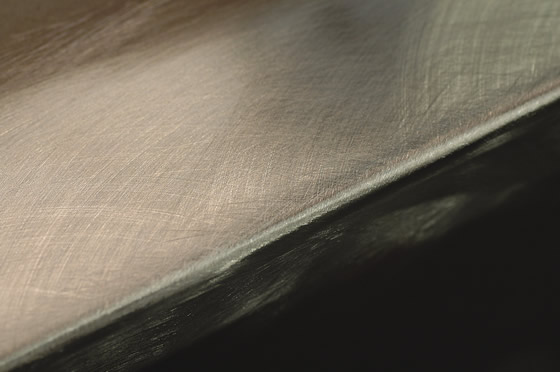

The results of roll grinding should look almost exactly like a formed bend produced on a brake.

Contrary to the paint-fill myth, parts show grinding scratches even after a light coat of flat paint is applied.

Paint is a coating with some thickness, but generally not enough to hide bad grinding work. Just ask someone at an auto body shop how smooth the surface should be prior to painting. The underlying surface must be smooth and free of scratches. Because most painted surfaces have some gloss to them, they tend to highlight any remaining scratches. I typically use a fine-grit abrasive and a final skim with a nonwoven abrasive like Scotchbrite to remove most of the offending deep scratches. CTE

About the Author

Tom Lipton is a career metalworker who has worked at various job shops and lives in Alamo, Calif. For more information, visit his blog at oxtool.blogspot.com and video channel at www.youtube.com/user/oxtoolco. Lipton’s column is adapted from information in his book “Metalworking Sink or Swim: Tips and Tricks for Machinists, Welders, and Fabricators,” published by Industrial Press Inc., South Norwalk, Conn. The publisher can be reached by calling (888) 528-7852 or visiting www.industrialpress.com. By indicating the code CTE-2015 when ordering, CTE readers will receive a 20 percent discount off the book’s list price of $44.95.

Related Glossary Terms

- abrasive

abrasive

Substance used for grinding, honing, lapping, superfinishing and polishing. Examples include garnet, emery, corundum, silicon carbide, cubic boron nitride and diamond in various grit sizes.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.