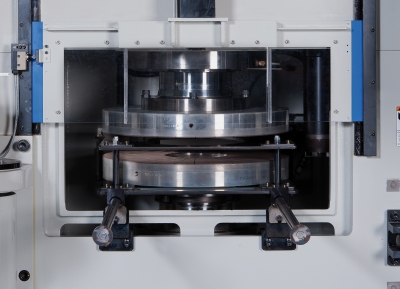

For the large-scale production of flat precision components Thielenhaus Microfinish says it presents a particularly cost-efficient, compact machining solution. In close collaboration with the Japanese mechanical engineers Nissei, the ultraprecision machine tool producers offer a double-disc grinding machine characterized by four advantages: precision, cost-effectiveness, ease of use and compactness.

During production, any expensive extra that wasn’t necessary for achieving the stipulated goal was foregone. Instead, it was precision that was of paramount importance: The focus of the design has therefore been laid on a high degree of rigidity: closed box frames instead of a C-frame, forged instead of turned tool spindles, clever positioning of spindle tilting mechanisms and a double-walled frame design for temperature insensitivity. Indeed, the allimportant dressing process requires such rigidity to create the appropriate tool geometries.

Other highlights include the spindle sleeve feed system in conjunction with a worm gear, the associated patented pneumatic compensation for thread play and high-precision ABEC-7 class bearings. Furthermore, effective standard features, such as an automatic tool-wear compensation system for the lower grinding disc by means of in-process measurement, are also included.

This leads to exceptional machining results. With steel precision discs with a diameter of 68 mm, for example, parallelism below 3 µm and surface results of Ra 3.2 µm can be achieved with a cycle time of 0.6 seconds. In another application, the machine achieves a removal of up to 0.6 mm per pass.

Ease of use is a further crucial advantage. A patented swivel transport disc bracket allows the operator to change the grinding discs easily through the large front opening just a few seconds after the spindles have come to a stop. With an adaptable tool-changing aid this can be done in just a few minutes. Depending on the tolerances to be achieved, workpieces can be machined using a flow, flow/plunge or oscillation process. For the highest component specifications, the workpieces can also be propelled in the grinding gap with the appropriate transport disc designs.

Nissei has managed to compress this vertical machining solution into a footprint of just 2 x 2.5 m including the control cabinet, which also makes it suitable for compact production lines. There are various automatic loading options for feeding and removing workpieces, ranging from stack magazines to robots. The vertical double-sided grinding machines are available in eight models with different grinding disc sizes up to a diameter of 760 mm. Depending on the machine model and process, rotationally symmetrical workpieces from a thickness of 0.8 mm and up to a diameter of 220 mm can be machined.

Whilst Nissei is responsible for the construction, installation and running-in of the client’s workpieces, all service aspects, including dealing with enquiries, advice, quotations and sample processing, through to commissioning, training, warranties and after-sales, are provided by the Thielenhaus team for Europe and North America. As a result, operators have the advantage of a local contact who can be reached quickly throughout the whole life cycle via the 24/7 service hotline. With this support, even small and medium-sized companies are able to purchase and operate a high-quality Japanese machine with a long service life and outstanding cost-effectiveness.

Contact Details

Related Glossary Terms

- dressing

dressing

Removal of undesirable materials from “loaded” grinding wheels using a single- or multi-point diamond or other tool. The process also exposes unused, sharp abrasive points. See loading; truing.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding machine

grinding machine

Powers a grinding wheel or other abrasive tool for the purpose of removing metal and finishing workpieces to close tolerances. Provides smooth, square, parallel and accurate workpiece surfaces. When ultrasmooth surfaces and finishes on the order of microns are required, lapping and honing machines (precision grinders that run abrasives with extremely fine, uniform grits) are used. In its “finishing” role, the grinder is perhaps the most widely used machine tool. Various styles are available: bench and pedestal grinders for sharpening lathe bits and drills; surface grinders for producing square, parallel, smooth and accurate parts; cylindrical and centerless grinders; center-hole grinders; form grinders; facemill and endmill grinders; gear-cutting grinders; jig grinders; abrasive belt (backstand, swing-frame, belt-roll) grinders; tool and cutter grinders for sharpening and resharpening cutting tools; carbide grinders; hand-held die grinders; and abrasive cutoff saws.