5ME’s Freedom 4.0 updates the popular Freedom eLOG software, with a focus on manufacturing efficiency that integrates seamlessly to provide full transparency into manufacturing processes. These include asset utilization, performance, quality and OEE, as well as machine health and process health. Recognizing patterns and trends allows finely tuned management of equipment operations, leading to increased productivity and profitability. The new software continues the Freedom eLOG tradition of providing real-time monitoring and analysis, machine diagnostics, and a comprehensive array of manufacturing metrics.

“As Industry 4.0 gains traction, manufacturers understand that there is a better way to gain efficiency. Today, manufacturing is exceedingly data-driven, less art and more science, per se,” said Pete Tecos, executive vice president marketing and product strategy for 5ME. “We’ve created a superior way to capture production models with an incredibly intuitive custom user interface. Access to precise data takes the guesswork out of the equation.”

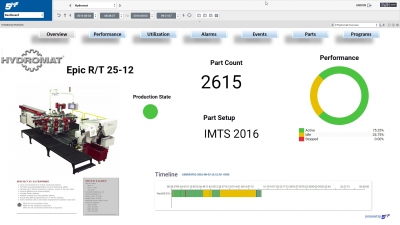

The system is a multi-tenant approach that offers segregation as well as customization for each user on the account. It provides unique options such as a 7-day survey view, enhanced reports with configurable graphics and data tables with sortable/selectable columns, collapsible menus, custom downtime categories, and flexibility to categorize unclassified time. It also features unlimited user-configured “watch” notifications to alert users or user groups of machine conditions and increased flexible machine schedules. Perhaps the most exciting new feature with Freedom 4.0 is SmartBoards (Smart Dashboards). It allows users to easily configure customized screens that incorporate data elements that are most important to them, as well as the ability to embed images, websites, work instructions, spec sheets, or any other salient information. “Freedom 4.0 is cloud deployable, and therefore eliminates the need for dedicated or virtual servers and the IT staff to maintain it,” added Tecos. “Intuitive software is an asset, but it becomes crucial when it helps bridge the gap between OT and IT.”

The feature rich IoT software is usable by small shops as well as global enterprises, where it can connect seamlessly with ERP, MES, CMMS, and quality business systems and can be accessed anytime via any device with a browser. Like its predecessor, Freedom 4.0 is fully MTConnect compliant.