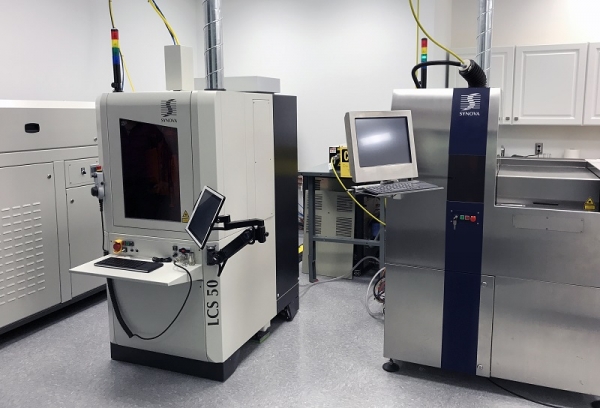

Synova, a leading manufacturer of high-precision laser cutting systems, opened a new Micro-Machining Center (MMC) in Secaucus, NJ, according to an April 10 company news release. The new MMC offers laser machining services such as application trials, single and recurring cutting jobs and machine demonstrations. The center will house two Laser MicroJet systems, the new 5-axis LCS 50 machine to be used for 3D shaping and machining, and the versatile LCS 300 for 2D machining of parts up to 300 mm x 300 mm in size.

Synova, a leading manufacturer of high-precision laser cutting systems, opened a new Micro-Machining Center (MMC) in Secaucus, NJ, according to an April 10 company news release. The new MMC offers laser machining services such as application trials, single and recurring cutting jobs and machine demonstrations. The center will house two Laser MicroJet systems, the new 5-axis LCS 50 machine to be used for 3D shaping and machining, and the versatile LCS 300 for 2D machining of parts up to 300 mm x 300 mm in size.

All Synova machines incorporate Synova’s unique water jet guided laser technology (Laser MicroJet®), which is based on the patented approach of entrapping a cylindrical laser beam within a hair-thin water jet, resulting in perfectly parallel walls, tight kerf widths, smooth cut surfaces and sharp edges. The technique enables the surface to be cooled by the water between laser pulses, thereby minimizing the heat affected zone and its related defects. The water also cleans the surface, reducing post-machining processing requirements.

“I am happy to add yet another Micro-Machining Center to our global network of offices,” said Dr. Bernold Richerzhagen, founder and present CEO of Synova. “Regional centers offer a novel way our customers can leverage the unique value of the Laser MicroJet technology for their specific application and needs.”

Said Dr. Benjamin Carron, global director of applications at Synova: “The LCS 50 is the perfect addition to our base LCS 300 capabilities. The 5-axis LCS 50-5 is an excellent solution for small parts such as natural and industrial diamond applications, and medical micro-parts, typically processed with 30 to 70-micron kerfs. Customers benefit from Synova’s unique expertise as an industrial micro-machining solutions provider; leveraging a knowledge base across multiple industries that have a common need for high precision and expanded hardware/software capabilities.”

For more information about MMC, contact Jacques Coderre via e-mail or call (510) 396 5664.

Related Glossary Terms

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- kerf

kerf

Width of cut left after a blade or tool makes a pass.

- laser machining

laser machining

Intensified, pulsed beams of light generated by lasers—typically carbon dioxide or neodium-doped yttrium aluminum garnet (Nd:YAG)—that drill, weld, engrave, mark, slit and caseharden. Usually under CNC, often at both high cutting rates (100 linear in./sec.) and high power (5kW or more). Lasers also are used in conjunction with in-process quality-control monitoring systems allowing measuring accuracies of 0.00001".

- parallel

parallel

Strip or block of precision-ground stock used to elevate a workpiece, while keeping it parallel to the worktable, to prevent cutter/table contact.

- shaping

shaping

Using a shaper primarily to produce flat surfaces in horizontal, vertical or angular planes. It can also include the machining of curved surfaces, helixes, serrations and special work involving odd and irregular shapes. Often used for prototype or short-run manufacturing to eliminate the need for expensive special tooling or processes.