With the latest version of QualityXpert, InspectionXpert Corp. and K2D-KeyToData GmbH offer the "next generation of quality-management software."

"We are really delighted, that this milestone of quality control is now just ahead of the final release”, emphasizes Jochen Layer, CEO of K2D-KeyToData GmbH. The new cloud-based version of the shop-floor quality system was intensively tested by 60 small and large companies.

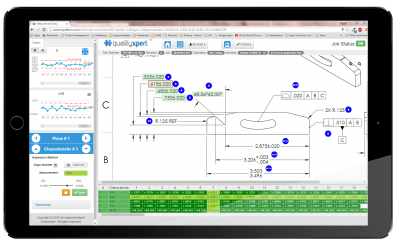

"For those who want shorter and more flexible production cycles, there are few alternatives than using this modern tool from InspectionXpert Corp. Finally, it is possible with this highlight, to reduce time and cost of production in a striking manner,” Layer said. "The goal of InspectionXpert Corporation was to create an innovative, cross-platform software for PC and tablet, optimized for shop floor, which combines all the essential areas of quality control and optimization of quality processes. Naturally this software had to be web-based."

A combination of the software solutions InspectionXpert OnDemand and the brand-new QualityXpert enables companies to work paperless from inspection drawing to the inspection report and process analytics. Processes are continuously optimized allowing the highest manufacturing quality to be reached. “Automating the creation of ballooned drawings and inspection plans become self-evident," Layer said. InspectionXpert OnDemand streamlines the generation of these from PDF drawings as well as native 2D & 3D CAD files: "The created inspection plans can then be published seamlessly to QualityXpert."

QualityXpert is a web-based in-process inspection software that can be used on PCs and tablets for powerful and fast quality inspections. Inspection planners, field service organizations, machine operators, quality and production managers can create inspection plans, capture measurements and report results in real time. Improved visibility enables more effective monitoring of critical manufacturing processes over time and improves quality decisions based on accurate and timely empirical data. The key focus of QualityXpert development is the essential tools for real time manufacturing quality management;

- Process flow diagram, PFD, pre-populated from inspection characteristics

- Process failure mode effects analysis, PFMEA pre-populated from PFD and inspection characteristics

- Control plan, CP, pre-populated from PFMEA, PFD and inspection characteristics

QualityXpert establishes traceability; any time a part’s measurement data is saved, the operator’s name, plus the date and time are captured. Additionally, when a part is measured as a nonconformance a configurable drop down appears, which includes the option to set the criteria for mandatory entries such as assignable cause, comment and corrective action.

These capabilities will help save time, reduce errors and ensure tighter version control. Reducing costs, including labor, rework, scrap and escapements, and speed production.

InspectionXpert OnDemand combines both PDF and CAD data into a single state-of-the-art and powerful product. Continuing our legacy of developing quality automation solutions that provide substantial time and cost savings through automating the inspection process.

- Create inspection/technical data packages from PDF, TIF, DWG, Catia, NX and Creo files with a single interface and save within a single inspection project

- Accurate recognition of GD&T feature control frames from PDF drawings

- Easily undo changes with undo/redo

- Easy to use, “heads-up” interface with time-saving features

- Standard integrations to QualityXpert and Verisurf

Use InspectionXpert OnDemand to create AS9102, PPAP or custom reports to meet quality inspection reporting needs or customer’s requirements. Capture results from hand tools and gauges to instantly see out-of-tolerance conditions. Import results from any CMM and correlate with print dimensions for instant reporting with no manual data entry.

Related Glossary Terms

- computer-aided design ( CAD)

computer-aided design ( CAD)

Product-design functions performed with the help of computers and special software.

- in-process gaging ( in-process inspection)

in-process gaging ( in-process inspection)

Quality-control approach that monitors work in progress, rather than inspecting parts after the run has been completed. May be done manually on a spot-check basis but often involves automatic sensors that provide 100 percent inspection.

- quality assurance ( quality control)

quality assurance ( quality control)

Terms denoting a formal program for monitoring product quality. The denotations are the same, but QC typically connotes a more traditional postmachining inspection system, while QA implies a more comprehensive approach, with emphasis on “total quality,” broad quality principles, statistical process control and other statistical methods.