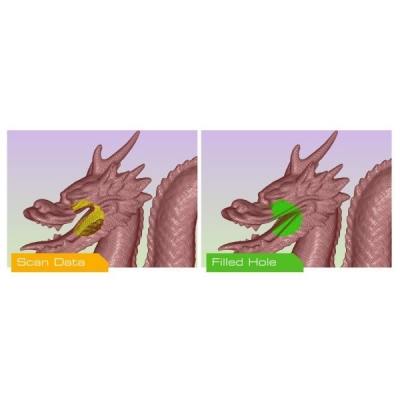

MachineWorks Ltd. is offering solutions for solving difficult 3D scanning problems such as complex hole filling in a point cloud of the 3D object. 3D scanners often produce 3D models with missing regions or with holes. Polygonica polygonal modeling software engine’s latest function addresses hole filling by recapturing the original geometry of the 3D data thanks to clever geometry manipulation.

New more efficient algorithms benefiting from multiple-threaded code have been developed to improve the performance of hole filling so that the completion of the model is achieved much faster. The Polygonica team has also developed new methods specifically aimed at much larger holes and the combination of closing holes faster and dealing with larger missing areas. Different complexities and sizes have been tested and the overall performance improvement is significant.

There is a new fill type which can match the features on opposite sides of a hole and extend them across the hole. This often gives much a better mesh result than finding a minimum area or smooth fill for the hole.

Filling annular holes (holes with one or more islands inside them) more effectively is also part of the new offering. The outer hole is filled while keeping the detail given by the islands. The new fill type automatically matches features to determine which islands belong to which hole giving extremely good results for filling holes in challenging scanned objects.

“We’re seeing increasing demand for processing and repairing scanned data in a range of sectors away from the specialist tools provided by scanner manufacturers themselves. We are very excited by the speed and quality of these new hole filling techniques and we look forward to bringing further improvements in future releases,” says Richard Baxter, sales manager for Polygonica at MachineWorks Ltd.