Offering both speed and strength, a new counterboring tool has what it takes to make the cut in a variety of challenging applications.

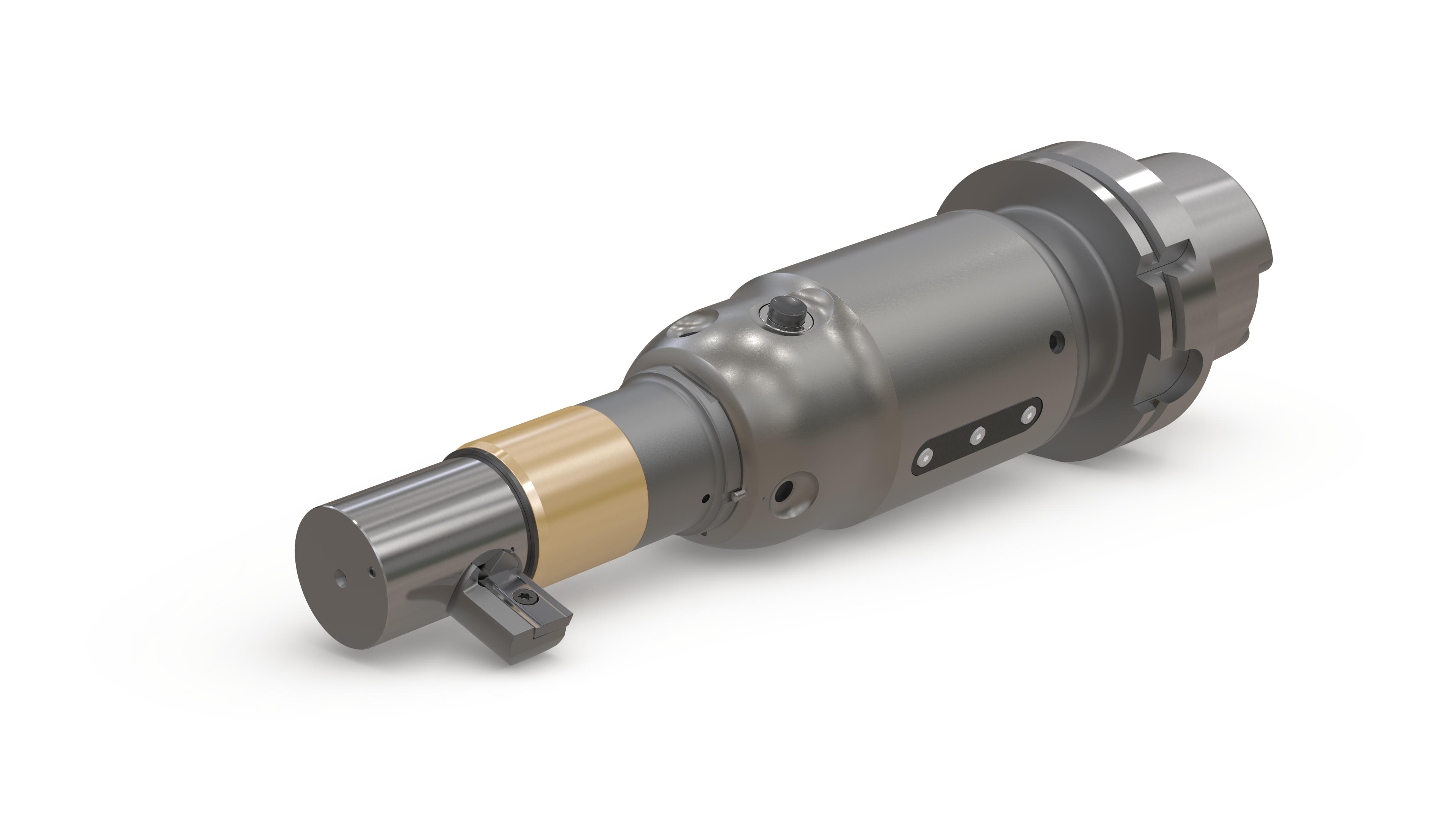

So says the manufacturer, Heule Tool Corp. in Loveland, Ohio, about the recently introduced Solo L spot facing and counterboring tool. Solo L can produce front and back counterbores up to 1.95 times bore diameter for applications with bores ranging from 25 mm to 45 mm in diameter.

Heule touts the tool’s simple and reliable design, which works without a contact mechanism, a change in spindle rotation or an anti-rotation device. The patented pin-driven system moves the cutting blade in and out radially, thereby preventing chips from interfering with the tool’s operation. The system employs two centrifugal weights installed in a sealed tool head that prevents coolant contamination. When a speed of 1,600 rpm is reached during the bore-cutting part of the process, the weights start moving outward and turn a gearwheel, which moves the blade out by rotating the blade control. Once the bore is cut and the spindle stops or slows to 900 rpm or less, a pullback spring pushes the centrifugal weights back to the center and the blade extends to cut the proper counterbore diameter.

The Solo L replaces an older Heule counterboring tool that also used a single cutting blade but “was much slower and more mechanical,” said Gary Brown, the company’s president. That tool, which employed a stop block anti-rotation device, took about twice as long to do its job, according to Brown.

“The new Solo L doesn’t require any sort of stop block,” he noted. “It’s a centrifugal force tool that activates at different rpms.”

In addition to this new Solo version, Heule currently offers three other Solo models that are also capable of counterboring 1.95 times the bore diameter. Brown pointed out, however, that the Solo L is the strongest automatic back counterbore tool Heule has ever produced. Capable of cutting nickel, titanium and exotic alloys, the system can also handle strenuous jobs that require interrupted cuts. “There is really nothing (else) out there that will take the interruptions,” he said.

According to Heule, the Solo L’s capabilities and features make it suitable for a wide variety of CNC, transfer, multi-spindle and conventional machining applications. Typical applications cited by Brown include cutting large counterbores in aircraft landing gear and vehicle axle tubes, as well as front and back cutting of planetary carriers for the automotive industry. “It's something unique for certain industries (because) it can do front and back facing,” he said.

To meet specific project requirements, Solo L features such as the cutting blade, blade housing and blade control are customizable. The tool’s adaptability allows it to work with vertical turning lathes and large open-air machines, Brown noted, adding that “we never had a product that could handle those before.”

Contact Details

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- counterbore

counterbore

Tool, guided by a pilot, that expands a hole to a certain depth.

- counterboring

counterboring

Enlarging one end of a drilled hole. The enlarged hole, which is concentric with the original hole, is flat on the bottom. Counterboring is used primarily to set bolt heads and nuts below the workpiece surface.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.