By Jim Nielsen

In many manufacturing processes, tapping can be a highly efficient method for high-volume hole threading in components. An effective tapping operation can make a major impact on productivity and the bottom line, enabling higher cutting speeds, reduced downtime and longer tool life. But when working with hard materials, things can get a little more complicated.

Whether you’re tapping hardened steels, nickels or any other material that goes higher than 38 on the Rockwell C scale, the challenges and risks increase significantly with the hardness of the material. Errors at this stage in the manufacturing process can be critical because tapping is typically one of the last operations to be completed on a component. A broken tool or scrapped component at this stage can mean hours, or even days, of machining time lost, not to mention the cost of the component.

Shops will need to overcome several key challenges when tapping harder materials. They’ll need to contend with slower cutting speeds, chip evacuation challenges and more tool wear.

Shops will also need to take much greater care with tool selection, hole preparation, lubrication and more to meet those challenges.

Here, we’ll look at some of the key considerations for achieving effective tapping operations in hard materials.

Select The Right Tap

For shops that are new to tapping hardened materials, they may make the common mistake of using standard steel or versatile tapping tools they have on hand. But without the right geometry, grade or tool coatings, tap tool life will decrease dramatically the harder a material gets on the Rockwell C scale.

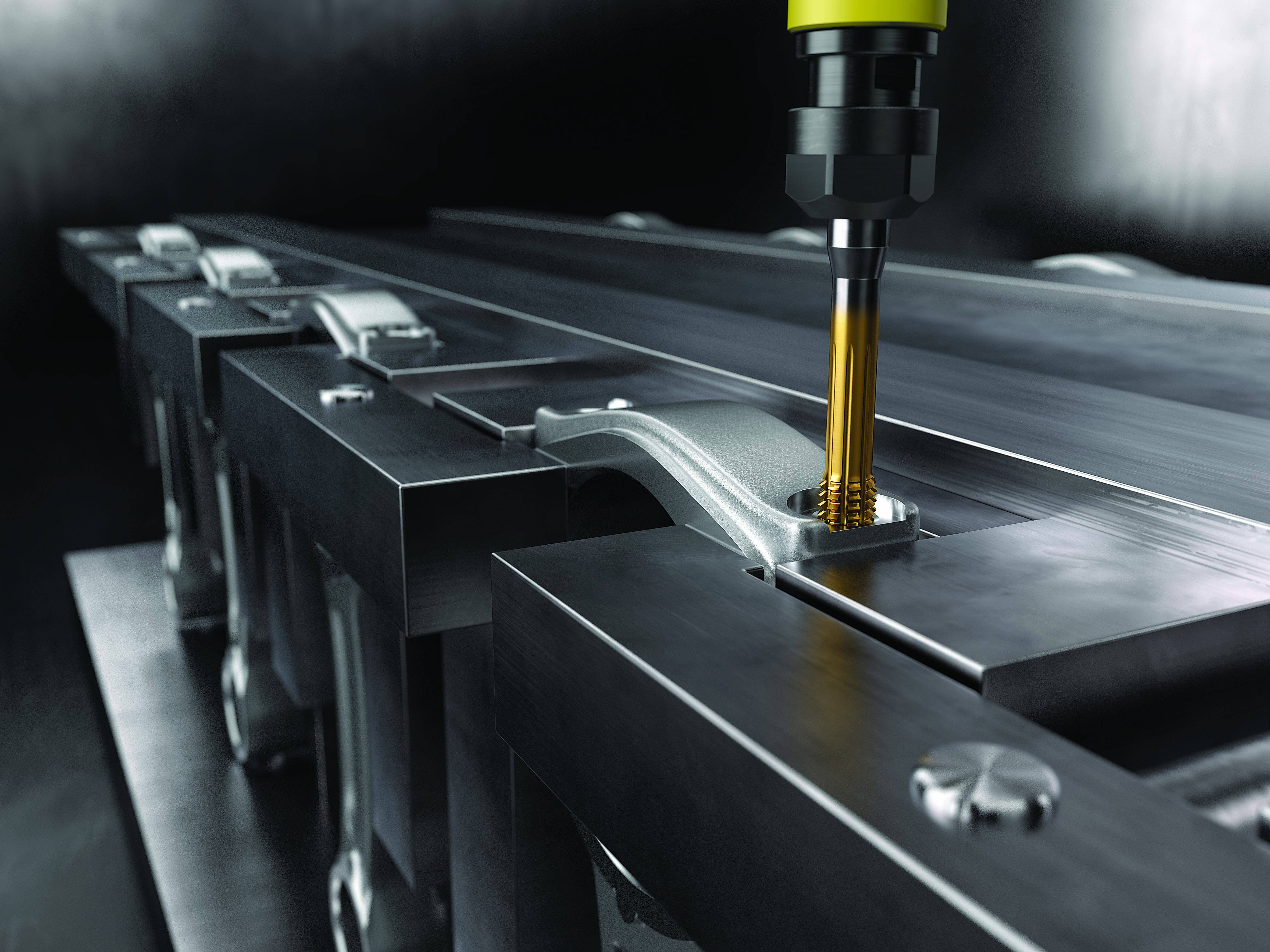

Using a geometry that’s optimized for hard materials can go a long way to improve operations. Straight-flute, spiral-point taps made from high-speed steel cobalt powdered metal provide a much tighter grain structure and greater wear resistance when tapping with through holes. For blind holes, optimized spiral flutes made from the same high-speed steel material are available. These geometries, combined with specialized coatings like titanium aluminum nitride, can significantly improve tool life, process security and overall productivity when tapping hard materials.

But how do you know when to start looking at optimized tapping tools? Generally speaking, that time has arrived when material hardness starts approaching 40 HRC. At that point, standard steel taps, form taps or versatile taps will not hold up well, if at all, in high-volume operations. It’s also important to note that once material hardness gets closer to 48 HRC, tapping may no longer be an option at all, and shops may need to turn to thread milling. For some one-off applications, specialized carbide straight-flute taps are available for tapping materials as hard as 60 HRC, but the majority of shops will want to use thread milling at that point.

Lubrication Matters

One of the most important factors to successful tapping is lubrication. Unfortunately, it’s also one of the most overlooked aspects of the operation. When errors start occurring in the tapping process, one of the first places to look is at the oil concentration levels in the coolant. In many cases, the concentration will be too low.

When tapping hard materials, using straight tapping oil is ideal. This may be possible if tapping is the only operation you’re running, but in most applications, shops are using a CNC machine for all kinds of operations, and they can’t run straight oil. Instead, they’ll need to run a water-soluble lubrication with the highest possible oil concentration. While standard tapping operations may run with 5% to 7% concentration, it’s best to push that up to at least 10% or 12% with harder materials.

Hole Prep Helps

When you’re tapping hard material, hole preparation becomes increasingly important for tool life and process security. Refer to an optimized pocket or wall chart and make the pre-hole as large as possible while still maintaining the class of fit you’re attempting to get with your thread gauge. This will make it easier on the tapping tool because it will have less material to remove, thus reducing wear and extending the life of the tool.

Slow Down Cutting Speeds

Once you’re ready to cut threads, it’s important to remember that harder materials will require significantly slower cutting speeds. While a tapping tool in softer material might be able to run at 150 sfm, tapping materials harder than 40 HRC will require speeds lower than 25 sfm. Once you get into the 44 HRC to 48 HRC range, cutting speeds will need to be as low as 8 sfm to 10 sfm.

Limit Depth of Blind Holes for Chip Control

Slower cutting speed also creates chip evacuation challenges on blind holes. Though operators won’t have to worry about long stringy chips with hard materials, a slower helix creates less auger action for the tool to pull chips up and out of the hole. Because of this, Sandvik recommends limiting the depth of blind holes in hard materials to no more than 2 × D.

Tap Drivers Improve Stability

Another important way to minimize wear on your tools and improve accuracy when tapping hard materials is with specialized chucks or tap drivers. Even though many machines today have rigid tapping cycles for secure tapping operations, those machines and their servos wear, which in turn can create a slight mismatch between the program feed and the actual feed.

To address this, shops can use toolholders for synchronized tapping that have a special coil built inside to provide micro compensations for inaccuracies in the machine. This improves tapping precision by providing accurate depths, and it reduces thrust force on the tap flanks. These tap drivers can be used in any tapping operation to minimize risk of oversized threading, improve process security and extend tool life.

Seek Advice from your Tool Provider

Every tapping operation will have its own unique challenges, whether it’s related to the material, the manufacturing process or production demands. Determining the best approach for tapping hard materials isn’t always cut and dry, but it’s important to remember that you don’t need to figure it out on your own.

Partnering with your tool provider eliminates the guesswork and is often the surest way to optimize your tapping operation and maximize productivity. The right provider will have the knowledge and expertise to help guide you to the proper tap selection, holding solution and operating parameters. They’ll also be able to help you find the best ways to avoid downtime, poor thread quality and scrap, getting you on your way to a more productive, more profitable operation right from the start.

Contact Details

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- flutes

flutes

Grooves and spaces in the body of a tool that permit chip removal from, and cutting-fluid application to, the point of cut.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- hardness

hardness

Hardness is a measure of the resistance of a material to surface indentation or abrasion. There is no absolute scale for hardness. In order to express hardness quantitatively, each type of test has its own scale, which defines hardness. Indentation hardness obtained through static methods is measured by Brinell, Rockwell, Vickers and Knoop tests. Hardness without indentation is measured by a dynamic method, known as the Scleroscope test.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- straight oil

straight oil

Cutting fluid that contains no water. Produced from mineral, vegetable, marine or petroleum oils, or combinations of these oils.

- tap

tap

Cylindrical tool that cuts internal threads and has flutes to remove chips and carry tapping fluid to the point of cut. Normally used on a drill press or tapping machine but also may be operated manually. See tapping.

- tapping

tapping

Machining operation in which a tap, with teeth on its periphery, cuts internal threads in a predrilled hole having a smaller diameter than the tap diameter. Threads are formed by a combined rotary and axial-relative motion between tap and workpiece. See tap.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

- titanium aluminum nitride ( TiAlN)

titanium aluminum nitride ( TiAlN)

Often used as a tool coating. AlTiN indicates the aluminum content is greater than the titanium. See coated tools.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

about the author

Jim Nielsen is a highly experienced round tool specialist at Sandvik Coromant with over 42 years in the machining and tooling industry. He can be reached at [email protected].