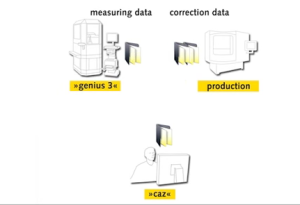

Controlling the process

Careful consideration when implementing inspection processes yields efficiencies. Manufacturers continually search for ways to increase profits and reduce costs. Trying to find cost savings where chips are made makes sense and is usually where the most-significant improvements are found. However, efficiency gains can also be made in nonvalue-adding areas, like inspection.