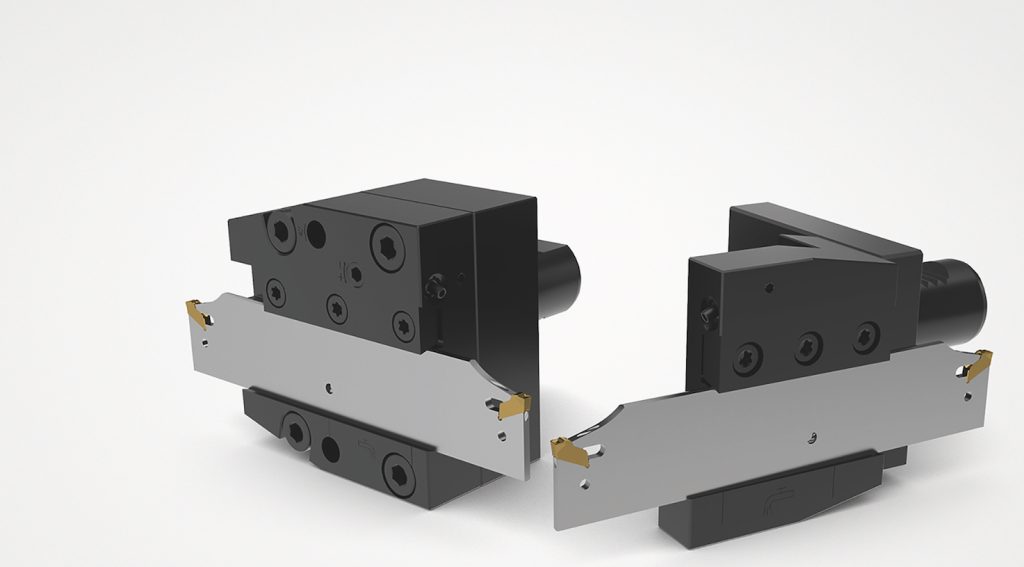

150.10‑JETI Family of Parting-Off Blades and Square-Shank Blocks

150.10‑JETI Family of Parting-Off Blades and Square-Shank Blocks

Seco Tools line of 150.10‑JETI family of parting-off blades and square-shank blocks now includes a new VDI block design. Adapters directly hold the 150.10-JETI parting-off blades onto the VDI turret and offer streamlined delivery of high-pressure coolant to the cutting zone without the use of hoses.

Seco Tools line of 150.10‑JETI family of parting-off blades and square-shank blocks now includes a new VDI block design. Adapters directly hold the 150.10-JETI parting-off blades onto the VDI turret and offer streamlined delivery of high-pressure coolant to the cutting zone without the use of hoses.

These blades and adapters quickly and efficiently remove heat during parting-off operations, resulting in high levels of productivity and long, predictable tool life, according to the company. Coolant is delivered internally to the adapter via the turret and then reaches the cutting zone through the coolant holes in the blades. The fast, direct transfer of coolant to the cutting edge is made possible by Seco's advanced Jetstream Tooling technology.

The 150.10-JETI family safely and effectively evacuates chips for better finished part quality and tool life. Adjustable edge heights optimize positioning.

The 150.10-JETI expansion includes face mount adapters for VDI30, VDI40 and VDI50 turrets and star mount adapters for VDI25, VDI30 and VDI40 turrets. The adapters hold 20-mm and 25-mm HSS parting-off blades. The range is also compatible with MDT reinforced blades with internal coolant.