Contact Details

Tungaloy has expanded its DrillMeister exchangeable-head drill system by adding 24 more DMH drill heads that are designed to resist fracture damage. This addition is for hole diameters ranging from 6.0 to 9.9 mm (from .236″ to .390″) and from 20.0 to 25.9 mm (from .787″ to 1.020″).

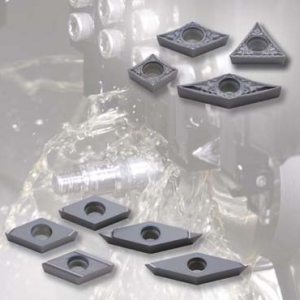

DrillMeister features superior cutting performance of solid carbide drills and the ease-of-use of the exchangeable head drill system. A single drill body can hold five different styles of drill heads, which are available in general purpose DMP style, DMC for high precision holes, DMF with flat edges ideal for counterboring, DMN for non-ferrous applications, and DMH with enhanced drill corner geometry for drilling thin plates.

The DMH drill head geometry is designed to protect drill corners and provide effective chip evacuation, making the drill head suited for applications that involve drilling holes through thin plates. The increased cutting edge strength resists thin-plate snapback and wear from exit burrs, preventing drill edges from fracture damage during machining for minimum machine downtime. The strong cutting edge also makes the DMH drill head suitable for drilling extremely hard metals.

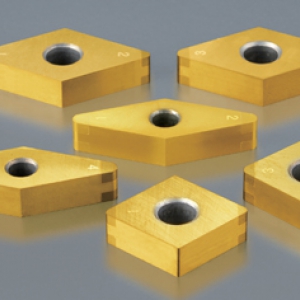

AH9130 grade provides DMH drill heads with a good balance of wear and fracture resistance, ensuring exceptional tool life performance and wear predictability, particularly in carbon steel and alloy steel.

Related Glossary Terms

- counterboring

counterboring

Enlarging one end of a drilled hole. The enlarged hole, which is concentric with the original hole, is flat on the bottom. Counterboring is used primarily to set bolt heads and nuts below the workpiece surface.

- flat ( screw flat)

flat ( screw flat)

Flat surface machined into the shank of a cutting tool for enhanced holding of the tool.

PRODUCTS

PRODUCTS