5-Axis Porting Option

5-Axis Porting Option

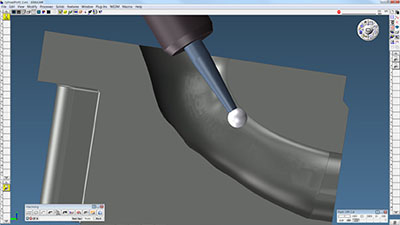

Gibbs and Associates announced the availability of its new 5-Axis Porting option for GibbsCAM.

Gibbs and Associates announced the availability of its new 5-Axis Porting option for GibbsCAM. The new software provides a specialized interface optimized for the machining processes and cutting tool motion required to machine tubular openings that change shape and curvature from one end to the other. The Porting option complements GibbsCAM 5-Axis by enabling easier and faster programming of port-like openings through a condensed interface that provides toolpath options and machining strategies optimized for machining such open shapes. Designed to accommodate the motorsports industry, where engine performance is frequently increased by optimizing flow through ports, manifolds and throttle bodies with specialized machining, the 5-Axis Porting option can increase the efficiency of programming and machining any parts with openings that change profile and curvature from end to end.

The software can automatically detect the spine curve through the port and properly align the toolpath. Using available tool reach, the software can split upper and lower operations automatically by maximum tool reach, midpoint or user selected percent of reach, ensuring proper toolpath blending between upper and lower sections. Machining strategies include roughing, rest roughing, and spiral and plunge (along) finishing. To maintain tool rigidity, 5-Axis Porting maintains 3-axis machining (3 + 2 mode) as far into the port as possible until 5-axis simultaneous motion is required. Tool tilting is automatically calculated for optimal angles, without the need to split surfaces or create tool axis control splines, producing smooth, gouge free 5-axis motion. Users may choose to machine only the top of a port, only the bottom, or both sides, in a single operation.

In addition to ease and speed, the GibbsCAM 5-Axis Porting option generates a cleaner, more efficient toolpath for faster machining and higher quality parts.