Abrasives App

Abrasives App

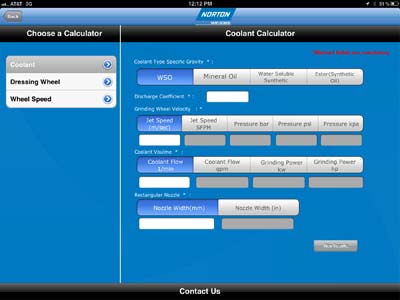

Saint-Gobain Abrasives has introduced a Norton Abrasives Grinding App.

Saint-Gobain Abrasives has introduced a Norton Abrasives Grinding App. This application includes three calculators including a wheel speed conversion calculator, as well as a coolant and dressing parameter calculator for abrasives applications. The Norton Grinding App also features a right angle grinding product selector and distributor locator. A link to Norton's abrasives connection and Web site to find and order product, check orders and inventory is available, in addition to a convenient button to contact Norton.

"With the increasing use of handheld digital technology, we are pleased to offer our customers with a convenient, simple-to-use grinding app," said Mr. David Long, Director of Marketing and Strategy at Norton Abrasives. "The app is designed for manufacturers to quickly simplify the process of calculating the requirements for their grinding application."

The new Norton Grinding App is available for IOS and Android operating systems on mobile devices. It can be downloaded for free at www.nortonindustrial.com/GrindingCalculationApp.aspx.