Contact Details

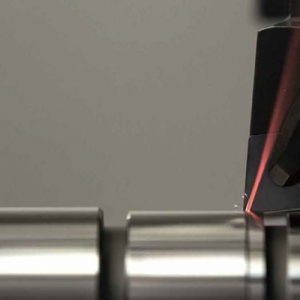

Tungaloy has announced the expansion of TungThread indexable threading tool series to include full profile threading inserts with the UN and UNJ profiles in AH8015 grade.

TungThread offers high-performance indexable threading tool solutions, extending over a broad range of threading applications from general parts that are machined in CNC lathes and small precision parts in Swiss-type automatic lathes to premium threading of OCTG.

A PVD-coated cemented carbide grade, AH8015 features an extremely hard high-aluminum content multilayer coating that is combined with a tough dedicated carbide substrate. The grade provides the insert with a well-balanced wear and chipping resistance.

New AH8015 grade threading inserts now offer the UN and UNJ profiles. The UN, or unified thread, is most commonly used on bolts, nuts, and a wide variety of other fasteners, while UNJ was developed to meet aerospace requirements for fatigue resistance. This expansion provides threading applications with long, predictable tool life, while keeping machining costs down, in not only steel and stainless steel but also difficult heat-resistant superalloys.

Related Glossary Terms

- computer numerical control ( CNC)

computer numerical control ( CNC)

Microprocessor-based controller dedicated to a machine tool that permits the creation or modification of parts. Programmed numerical control activates the machine’s servos and spindle drives and controls the various machining operations. See DNC, direct numerical control; NC, numerical control.

- fatigue

fatigue

Phenomenon leading to fracture under repeated or fluctuating stresses having a maximum value less than the tensile strength of the material. Fatigue fractures are progressive, beginning as minute cracks that grow under the action of the fluctuating stress.

- fatigue resistance

fatigue resistance

Ability of a tool or component to be flexed repeatedly without cracking. Important for bandsaw-blade backing.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- threading

threading

Process of both external (e.g., thread milling) and internal (e.g., tapping, thread milling) cutting, turning and rolling of threads into particular material. Standardized specifications are available to determine the desired results of the threading process. Numerous thread-series designations are written for specific applications. Threading often is performed on a lathe. Specifications such as thread height are critical in determining the strength of the threads. The material used is taken into consideration in determining the expected results of any particular application for that threaded piece. In external threading, a calculated depth is required as well as a particular angle to the cut. To perform internal threading, the exact diameter to bore the hole is critical before threading. The threads are distinguished from one another by the amount of tolerance and/or allowance that is specified. See turning.

PRODUCTS

PRODUCTS