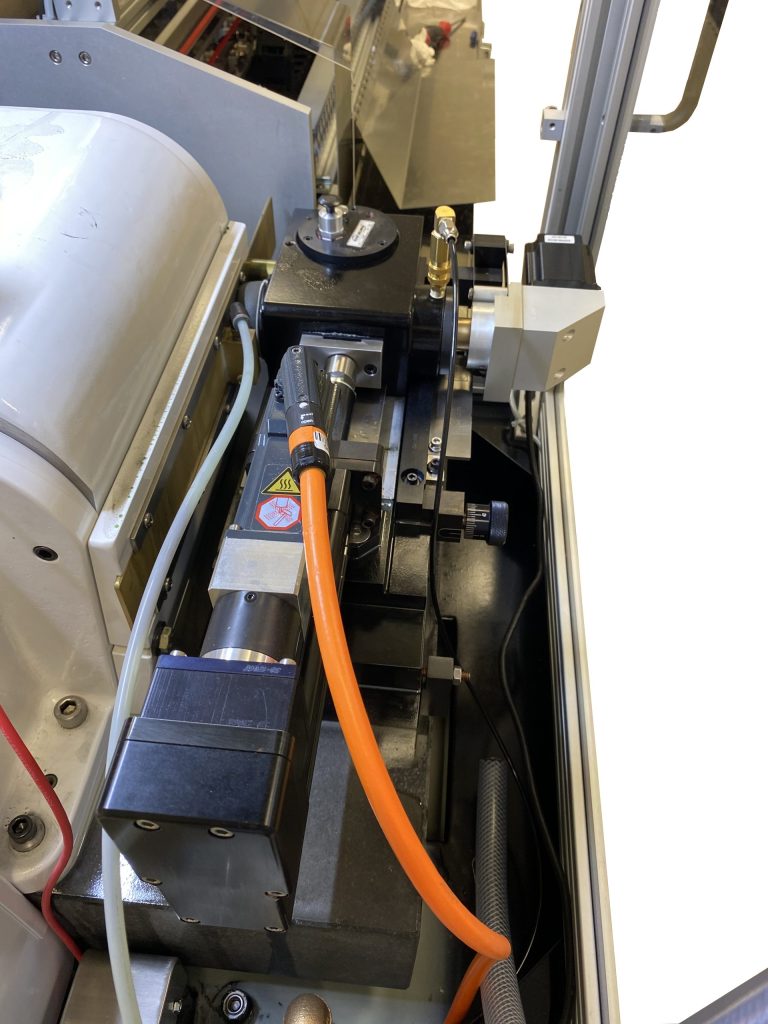

Automatic Wheel Dresser

Automatic Wheel Dresser

Glebar's automatic dresser is available with manual or motorized quill advancement. With motorized quill advancement, it is possible to have a canned dress cycle. Operators can preprogram the frequency of the dress to run after a set number of cycles or time. This allows them to run multiple machines at once increasing their efficiency.

Dressing the work wheel is an essential process to maintain a true wheel face. It ensures a smooth, consistent grind, improves machine efficiency, and minimizes scrap rates.

Glebar's automatic dresser is available with manual or motorized quill advancement. With motorized quill advancement, it is possible to have a canned dress cycle. Operators can preprogram the frequency of the dress to run after a set number of cycles or time. This allows them to run multiple machines at once increasing their efficiency. "Operators can initiate the automatic dressing cycle from the HMI leaving them free to perform other tasks," explained Mark Scanel, VP and GM of Glebar Customer Care.

In addition, operators can control the traverse rate producing a more controllable and predictable wheel dress in both the regulating wheel and work wheel. Having greater control improves the surface quality of the part being ground reducing scrap rates and increasing output.

The automatic dresser is available on Glebar's TF-9DHD Micro Grinder and all GT-610 Infeed/Thrufeed Centerless Grinding Machines.