Contact Details

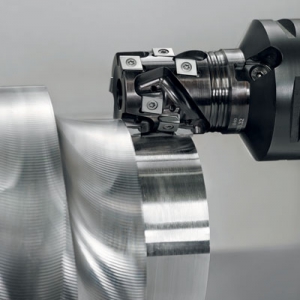

Walter has unveiled the Walter BLAXX M3024 heptagon milling cutter, the latest entry in its line of high-productivity milling tools. The M3024, in diameters from 1.5" to 6.0" (40mm to 160mm) boasts the line's trademark wear-protected black tool body, plus indexable inserts with 14 cutting edges, which reduces tooling costs.

For increased productivity the inserts are formed of Walter’s advanced cutting tool material, Tiger·tecSilver. Tiger-tec Silver is available in two CVD coated grades (WKP25S, WKP35S) for the machining of steel and cast iron, and three PVD coated grades (WSM35S, WKK25S and WSP45S) for the machining of steel, stainless steel, cast iron and difficult to cut materials.

Further, the inserts are secured by Torx Plus screws, adding an extra level of stability, and thus process reliability. In addition, a screw-secured solid carbide shim provides optimal support and high feed per tooth, plus optimal contact in the pocket.

Along with a higher level of reliability and lower tooling costs, the new Walter BLAXX M3024 heptagon milling cutter boasts a high metal-removal rate, even on low-performance machines, thanks to its positive cutting action. The M3024 comes in three geometries: The F27, the F57 and the F67, which optimize stability, universal application, and easy cutting action, respectively.

Related Glossary Terms

- chemical vapor deposition ( CVD)

chemical vapor deposition ( CVD)

High-temperature (1,000° C or higher), atmosphere-controlled process in which a chemical reaction is induced for the purpose of depositing a coating 2µm to 12µm thick on a tool’s surface. See coated tools; PVD, physical vapor deposition.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

- physical vapor deposition ( PVD)

physical vapor deposition ( PVD)

Tool-coating process performed at low temperature (500° C), compared to chemical vapor deposition (1,000° C). Employs electric field to generate necessary heat for depositing coating on a tool’s surface. See CVD, chemical vapor deposition.

PRODUCTS

PRODUCTS