Contact Details

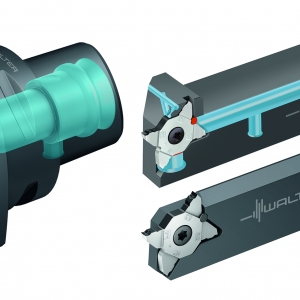

Walter is offering its counterboring and precision boring tools with connections for Walter Capto adapters. The versatile and time saving Capto interface is being increasingly used on lathes, machining centers and multitasking machines to allow these machines to perform multiple processes with only a single tooling interface. Now, by offering connections to its Walter Capto adapters in addition to its NCT and ScrewFit connections, Walter is bringing the benefits of Capto technology to its line of counterboring and precision boring tools. The connections are available in five coupling sizes, allowing them to be used on both small and large machines.

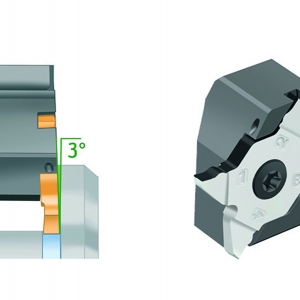

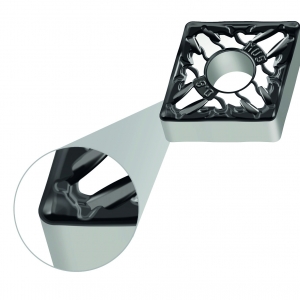

Walter boring tools comprise twin-insert models with medium and maxi versions for holes of 0.787-25.17" (20-640mm). This stable and compact boring system has an internal coolant supply and is suitable for symmetrically or radially displaced roughing operations.

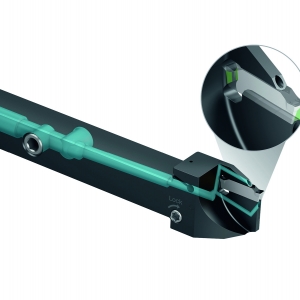

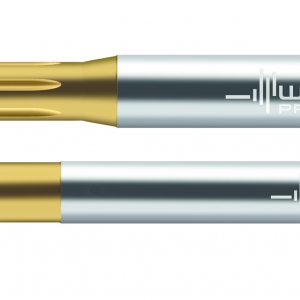

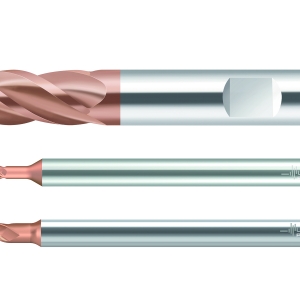

Walter precision boring tools include solid carbide and single insert tools with mini, medium and maxi versions for holes of 0.787-25.17" (2-640mm). Depending on the hole diameter, either boring-bar, cartridge or bridge constructions made of aluminum are used.

Walter PrecisionDIGITAL are single-edged precision boring tools for the most precise holes with a diameter of 0.118 to 4.882" (3-124mm). Their optoelectronic encoder makes it possible to readµm-precise digital results. For holes with a diameter up to 0.39" (10mm), solid carbide boring bars are available; for large diameters, bridges are available. The tool can be used up to a speed of 16,000 rpm.

Users of the Capto variants of this system will have a range of additional advantages: The interface is clamped using a conical polygon in accordance with ISO 26623, with a small cone angle. This creates a high clamping force and a good support face. The force is evenly distributed around the circumference of the polygon. The connection is completely backlash-free, is self-centering and does not need any special locking device. The Capto adapter is also shorter and therefore more resistant to bending than other adaptors, and the tendency to vibrate is correspondingly lower. This is especially useful in precision boring with its requirement for higher quality.

Related Glossary Terms

- boring

boring

Enlarging a hole that already has been drilled or cored. Generally, it is an operation of truing the previously drilled hole with a single-point, lathe-type tool. Boring is essentially internal turning, in that usually a single-point cutting tool forms the internal shape. Some tools are available with two cutting edges to balance cutting forces.

- centers

centers

Cone-shaped pins that support a workpiece by one or two ends during machining. The centers fit into holes drilled in the workpiece ends. Centers that turn with the workpiece are called “live” centers; those that do not are called “dead” centers.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- counterboring

counterboring

Enlarging one end of a drilled hole. The enlarged hole, which is concentric with the original hole, is flat on the bottom. Counterboring is used primarily to set bolt heads and nuts below the workpiece surface.

- multifunction machines ( multitasking machines)

multifunction machines ( multitasking machines)

Machines and machining/turning centers capable of performing a variety of tasks, including milling, drilling, grinding boring, turning and cutoff, usually in just one setup.

PRODUCTS

PRODUCTS