Contact Details

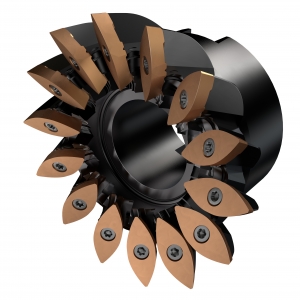

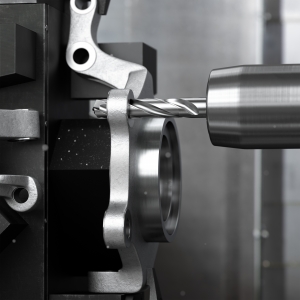

Sandvik Coromant, is introducing two new ceramic insert grades that are capable of performing high-speed, high-security turning operations on components made from demanding HRSA (heat-resistant superalloy) materials. The CC6220 and CC6230 ceramic grades are developed to machine demanding materials where whisker ceramics and SiAlONs fall short. Their ability to handle higher cutting speeds contributes to reduced cost per component, while inherent machining security ensures that quality is not compromised. This helps manufacturers produce high-quality parts time after time.

There is growing demand for aerospace engine parts that can withstand extreme temperatures beyond the capability of those made from Inconel and other high-performance superalloys. Although these powder metallurgic materials can be tailored to handle substantially higher temperatures, they are more difficult to machine than common HRSAs.

“CC6220 and CC6230 excel when turning demanding materials in intermediate stage machining,” says Rolf Olofsson, product manager for turning at Sandvik Coromant. “They take productivity to a new level in comparison to whisker ceramics and SiAlONs, in terms of both cutting speeds and feeds. Moreover, repeatable quality is assured.”

Along with productivity improvements of more than 50 percent over whisker ceramics and SiAlONs, CC6220 and CC6230 offer long tool life with challenging HRSAs, and thereby lower cost per part.

One of the most common applications to benefit is expected to be turbine disc turning. In a customer example that involved machining a low-pressure turbine (LPT) disc made from Rene material (42-45 HRC) as part of the intermediate stage machining process, a CC6220 RPGX insert was deployed to perform pocketing, while CC6230 RPGX inserts were deployed for rough-turning operation at cutting speeds as high as 400 m/min (1380 sfm). The process achieved a metal-removal rate (MRR) of 80 cm3/min (5 in3/min).

Similar success was achieved for a subsequent semifinishing operation at a lower cutting speed and long time in cut. Importantly, all of the specified quality requirements were attained on a repeatable basis, thanks to the process security provided by the new grade.

Aside from the aerospace industry, other sectors expected to benefit from CC6220 and CC6230 include power generation (turbine components in Inconel and Hastelloy), and oil and gas (parts cladded with Stellite 6, for example).

Related Glossary Terms

- ceramics

ceramics

Cutting tool materials based on aluminum oxide and silicon nitride. Ceramic tools can withstand higher cutting speeds than cemented carbide tools when machining hardened steels, cast irons and high-temperature alloys.

- cutting speed

cutting speed

Tangential velocity on the surface of the tool or workpiece at the cutting interface. The formula for cutting speed (sfm) is tool diameter 5 0.26 5 spindle speed (rpm). The formula for feed per tooth (fpt) is table feed (ipm)/number of flutes/spindle speed (rpm). The formula for spindle speed (rpm) is cutting speed (sfm) 5 3.82/tool diameter. The formula for table feed (ipm) is feed per tooth (ftp) 5 number of tool flutes 5 spindle speed (rpm).

- lapping compound( powder)

lapping compound( powder)

Light, abrasive material used for finishing a surface.

- metal-removal rate

metal-removal rate

Rate at which metal is removed from an unfinished part, measured in cubic inches or cubic centimeters per minute.

- superalloys

superalloys

Tough, difficult-to-machine alloys; includes Hastelloy, Inconel and Monel. Many are nickel-base metals.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

PRODUCTS

PRODUCTS