Cleaning Baskets with Open Design

Cleaning Baskets with Open Design

The optimal cleaning effect is achieved when the workpieces in the basket are easily accessible from all sides for the process technology and the media. To facilitate this, Metallform produces workpiece holders and baskets for bulk parts from stainless steel rounds.

These days, defined cleanliness specifications are common in component production across virtually all sectors. To comply with these requirements, some companies are investing vast sums in systems engineering and process technology. However, one major factor is often not considered: the cleaning basket. This is critical as the cleaning basket influences effectiveness of the costly process technology significantly, and thus the costs of cleaning.

In most cases, adapting or optimizing a cleaning process revolves around systems engineering, process technology and the cleaning media. What tends to be forgotten is that process technology such as ultrasonics, spray jets and cleaning media may only work to best effect on parts to be cleaned when they can reach those parts properly, and it is the cleaning basket used that determines the level of effectiveness. Incorporating baskets and workpiece holders into the considerations at an early stage is therefore worthwhile.

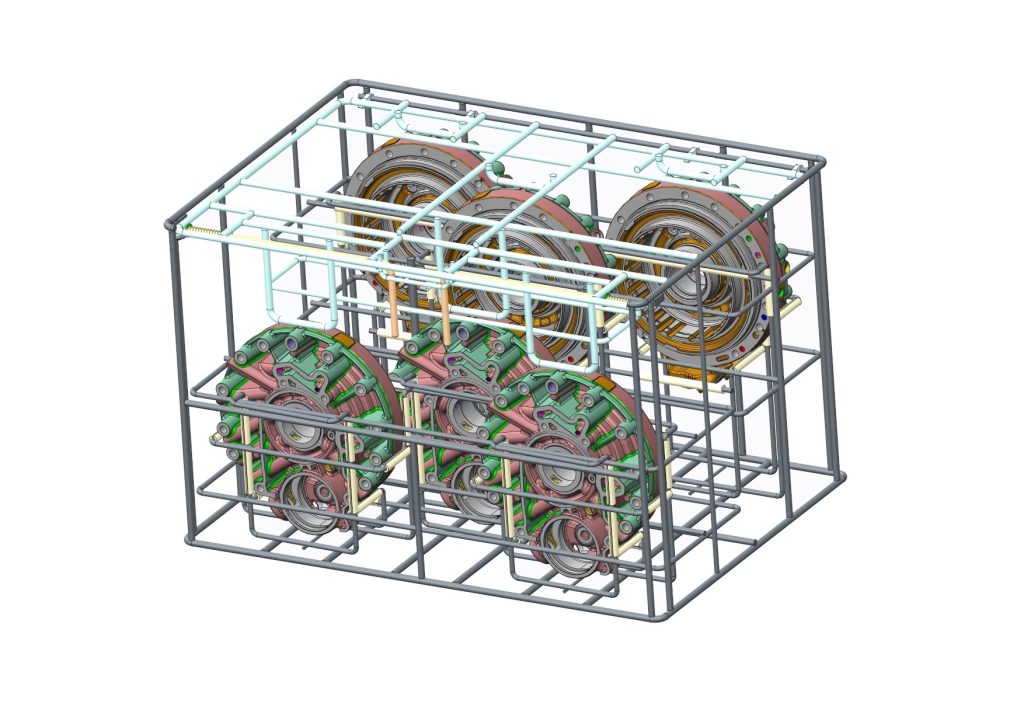

The optimal cleaning effect is achieved when the workpieces in the basket are easily accessible from all sides for the process technology and the media. To facilitate this, Metallform produces workpiece holders and baskets for bulk parts from stainless steel rounds. In contrast to boxes from perforated metal sheets that are still often used, these baskets have no enclosed surfaces, corners and edges. Therefore, ultrasonics and spray jets have unfettered access to parts and can take maximum effect. At the same time, the open design ensures an effective exchange of media.

On the one hand, removed contaminant is flushed from the basket quickly and can be removed by the filter and the accumulation of contamination in the basket is inhibited. On the other hand, the carry-over of cleaning media is minimized, resulting in longer periods between bath changes and thus improved system availability. In addition, the open basket design allows cost savings in the drying process, as the easy accessibility of parts reduces the drying time required.

Early integration of cleaning baskets also enables these to be adapted effectively to the cleaning machine and the workpieces to be cleaned. One consideration in this context is the optimal positioning of components in the workpiece holder. To achieve this, Metallform uses CAD technology. The optimal positioning of components enables the process technology being used to access critical areas such as specific bore holes and undercuts. In this way, particles and film-like contamination are quickly and reliably removed and the effective, resource-efficient drying of parts is assured. Another design feature is the minimizing of contact points between the component and the workpiece holder. This also helps to ensure cleaning of consistent quality within a short time.

Metallform produces all workpiece holders and baskets from stainless steel rounds with electrolytic polished surfaces. With good reason: This high quality, durable material is suitable for all cleaning media and prevents components from being recontaminated by the workpiece holder and baths from being contaminated by corrosion and zinc separation. Aside from the design and material, the workmanship of the cleaning baskets is equally convincing. All joints are completely welded and there are no sharp corners, edges or wire ends that could cause injury.

A basket designed for optimal cleaning may not improve the cleaning machine, but it ensures that process technology, which is generally expensive, can work to maximum effect.