Contact Details

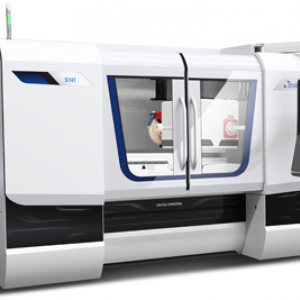

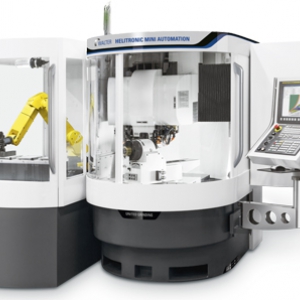

UNITED GRINDING has introduced a compact wheel changer for use on its WALTER HELITRONIC MINI POWER grinding

machines and HELITRONIC DIAMOND EVOLUTION two-in-one eroding and grinding systems. The automated changer provides more setup and part processing flexibility as well as boosts overall output through continuous uninterrupted machine operation.

Because of its size, the new wheel changer does not increase a machine’s footprint, so shops can add the automation while conserving valuable factory floor space. The wheel changer accommodates up to six grinding wheel sets or electrodes with maximum diameters of 150 mm. It also features a newly developed belt-driven spindle that increases the grinding/eroding length by up to 40 mm over the maximum length of a conventional MINI POWER with its two spindle ends.

Related Glossary Terms

- grinding

grinding

Machining operation in which material is removed from the workpiece by a powered abrasive wheel, stone, belt, paste, sheet, compound, slurry, etc. Takes various forms: surface grinding (creates flat and/or squared surfaces); cylindrical grinding (for external cylindrical and tapered shapes, fillets, undercuts, etc.); centerless grinding; chamfering; thread and form grinding; tool and cutter grinding; offhand grinding; lapping and polishing (grinding with extremely fine grits to create ultrasmooth surfaces); honing; and disc grinding.

- grinding wheel

grinding wheel

Wheel formed from abrasive material mixed in a suitable matrix. Takes a variety of shapes but falls into two basic categories: one that cuts on its periphery, as in reciprocating grinding, and one that cuts on its side or face, as in tool and cutter grinding.

PRODUCTS

PRODUCTS