Contact Details

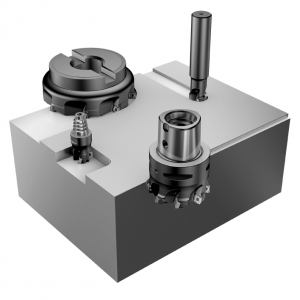

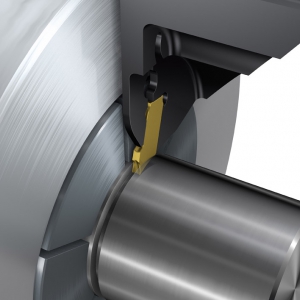

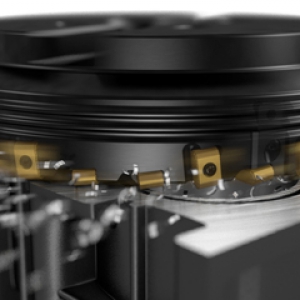

Sandvik Coromant introduced a new full profile hob for gear milling, CoroMill 176. This indexable carbide insert hob can reduce your cutting time by 50 percent and more than double your tool life compared to traditional high speed steel cutters.

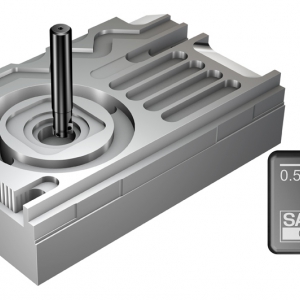

For roughing, semi-finishing and finishing, the innovative hobbing tool solution covers gear profile sizes in the range module 4-6. With standard carbide inserts for gear profiles according to DIN3972-2 it is custom-made for specific profiles with, for example, addendum modification and protuberance.

The hob is extremely easy-to-use with the iLock interface ensuring precision and stability. CoroMill 176 is registered as Quality class B in accordance with DIN3968.

Related Glossary Terms

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

PRODUCTS

PRODUCTS