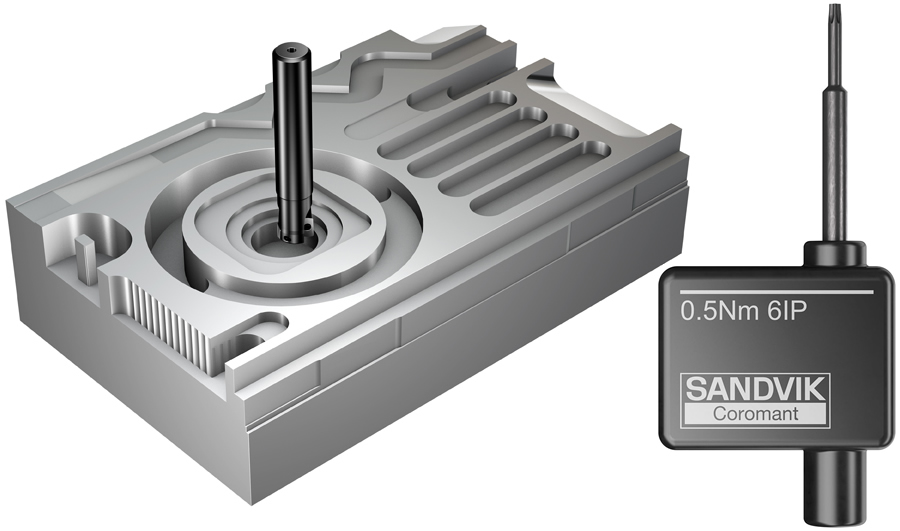

CoroMill 390 with size 07 inserts

CoroMill 390 with size 07 inserts

Sandvik Coromant recently introduced a new endmill for small diameters, the CoroMill 390 with size 07 inserts is said to be a versatile cutter ideal for shoulder milling, deep shoulder milling, edging, linear and helical ramping, plunge milling, slot milling and face milling, according to the company.

Sandvik Coromant recently introduced a new endmill for small diameters, the CoroMill 390 with size 07 inserts is said to be a versatile cutter ideal for shoulder milling, deep shoulder milling, edging, linear and helical ramping, plunge milling, slot milling and face milling, according to the company.

Suitable for all machine types, the CoroMill 390 with size 07 inserts also is said to be suitable for mixed production and can be used with different materials and applications.

Grades for the CoroMill 390 with size 07 inserts are available for all of materials. The new insert grade GC1130, produced with Zertivo technology, reportedly gives this cutter an extra dimension of security when milling steel. The smaller inserts deliver higher cutter-teeth density for superior productivity, according to Sandvik.

Unique to this tool is a torque key that's specifically designed for size 07 inserts. The key, which has built-in spring functionality, allows users to mount inserts with the correct clamping force for reliable and consistent tool life. In addition, coolant-through technology is standard on the CoroMill 390 with size 07 inserts for additional heat and chip control.