Contact Details

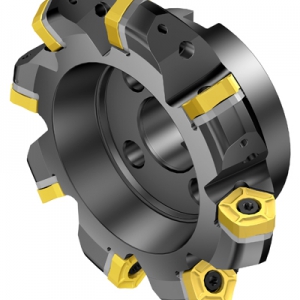

For longitudinal and face turning, Sandvik Coromant introduces the CoroTurn 300 for higher component quality, increased handling efficiency and longer tool life in steel turning operations. The CoroTurn 300 features stable insert clamping, as well as eight-edged inserts for the high chip control, tool life and surface finish.

Stable insert clamping for the CoroTurn 300 is made possible through the patented iLock interface. This system securely locks the insert in place to prevent cutting forces from affecting the tool position. iLock provides tool accuracy within ±0.05 mm (0.002 inch), giving the operator indexing repeatability for a better surface finish and increased tool life.

The eight-edged inserts for the CoroTurn 300 are available in grades GC4325 and GC4315 featuring Inveio coating, a unidirectional crystal orientation for high wear resistance and long tool life. The unique insert design has excellent chip breaking capabilities and less carbide per edge, which reduces the impact on our environment with less material to waste or recycle. Plus more edges allows for better inventory control.

Another way the CoroTurn 300 offers chip breaking capabilities is through high-precision (HP) over and under coolant. Coolant from above controls the chip breaking for secure machining while under coolant controls the temperature for long and predictable tool life. Other features of the tool are the Coromant Capto interface in a variety of sizes and the Quick Start (QS) shanks, which enable quick tool changes and easy coolant connections for maximized production time.

John Winter, turning product specialist for Sandvik Coromant, said, “The CoroTurn 300 integrates the latest advances in iLock, Inveio and high-precision coolant technology to take steel turning into the next century using an insert with eight, 80 degree cutting edges. This is the perfect tool for high volume outer diameter (OD) steel turning applications where tool life and process security is a must.”

Application specialist for general turning, Stefan Wernh, said, “CoroTurn 300 is designed to achieve outstanding performance in a turning process and the handling efficiency maximizes the machine utilization.”

Related Glossary Terms

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- outer diameter ( OD)

outer diameter ( OD)

Dimension that defines the exterior diameter of a cylindrical or round part. See ID, inner diameter.

- turning

turning

Workpiece is held in a chuck, mounted on a face plate or secured between centers and rotated while a cutting tool, normally a single-point tool, is fed into it along its periphery or across its end or face. Takes the form of straight turning (cutting along the periphery of the workpiece); taper turning (creating a taper); step turning (turning different-size diameters on the same work); chamfering (beveling an edge or shoulder); facing (cutting on an end); turning threads (usually external but can be internal); roughing (high-volume metal removal); and finishing (final light cuts). Performed on lathes, turning centers, chucking machines, automatic screw machines and similar machines.

- wear resistance

wear resistance

Ability of the tool to withstand stresses that cause it to wear during cutting; an attribute linked to alloy composition, base material, thermal conditions, type of tooling and operation and other variables.

PRODUCTS

PRODUCTS