Contact Details

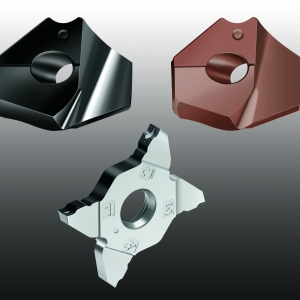

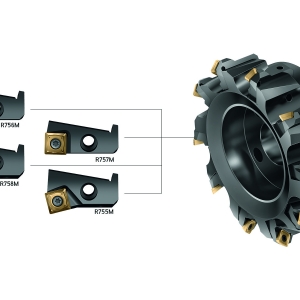

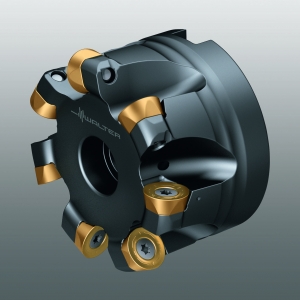

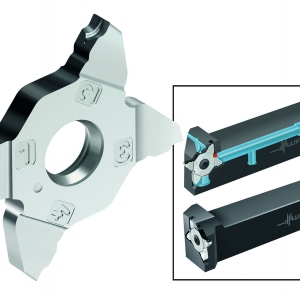

Walter has added additional sizes and designs to its Walter Cut-SX single-edged grooving system for grooving and parting. With the expanded line-up of Walter Cut-SX the cutting depth of grooves is no longer limited to the length of the insert, as it had been with double-edged systems. This makes it possible to achieve deeper grooving and parting cuts that are increasingly required in many sectors of industry.

Process reliability is enhanced by Walter Cut-SX's self-clamping inserts. This is made possible by having precisely matched grooving inserts and insert holders, a positive locking insert shape with form fit underside and a sturdy top clamp. A major advantage of this design is that in comparison to conventional inserts fitted at a straight angle, process reliability is significantly increased because a positive locking insert cannot be "lost" during machining. This is particularly important with parting, where there is always a risk that an insert can be pulled from the holder by the action of the workpiece and the bar separating.

Additionally, because grooving or parting applications may inhibit externally applied coolant from reaching the cutting edge, the Walter Cut-SX G2012-P toolholder features internal coolant delivered directly to the cutting edge, both with and without high pressure. Initial customer results show this can increase tool life by as much as 200 percent.

In the future, Walter will offer its Walter Cut-SX G2042R/L grooving blades with strengthened shank in four variants: As a left- or right-handed tool, each in a standard and a contra version. This makes it possible to work in any position required, even where space may be limited. Because the tool shank reduces available clearance when grooving in the immediate vicinity of the spindle, the mirror-image design of the contra version provides an easy solution to this potential problem.

Walter Cut-SX G2012-P toolholders with through coolant are available in the inch shank sizes of ½", 5⁄8", ¾" and 1". Walter has now added the metric shank sizes of 12 and 16mm (0.47 and 0.63") for smaller diameters to complement the 20 and 25mm shanks already available.

Related Glossary Terms

- clearance

clearance

Space provided behind a tool’s land or relief to prevent rubbing and subsequent premature deterioration of the tool. See land; relief.

- coolant

coolant

Fluid that reduces temperature buildup at the tool/workpiece interface during machining. Normally takes the form of a liquid such as soluble or chemical mixtures (semisynthetic, synthetic) but can be pressurized air or other gas. Because of water’s ability to absorb great quantities of heat, it is widely used as a coolant and vehicle for various cutting compounds, with the water-to-compound ratio varying with the machining task. See cutting fluid; semisynthetic cutting fluid; soluble-oil cutting fluid; synthetic cutting fluid.

- grooving

grooving

Machining grooves and shallow channels. Example: grooving ball-bearing raceways. Typically performed by tools that are capable of light cuts at high feed rates. Imparts high-quality finish.

- parting

parting

When used in lathe or screw-machine operations, this process separates a completed part from chuck-held or collet-fed stock by means of a very narrow, flat-end cutting, or parting, tool.

- shank

shank

Main body of a tool; the portion of a drill or similar end-held tool that fits into a collet, chuck or similar mounting device.

- toolholder

toolholder

Secures a cutting tool during a machining operation. Basic types include block, cartridge, chuck, collet, fixed, modular, quick-change and rotating.

PRODUCTS

PRODUCTS