DIT 716 Series Diamond Dressing Tool

DIT 716 Series Diamond Dressing Tool

Many years ago, the Super 716 Series diamond tool was made for dressing large and wide precision grinding wheels on centerless, cylindrical and surface precision grinding machines. They were made to minimize glazing and the closing up of the wheel surface. They were also made to carry the large wheel without taper or the crushing of the bond. It worked better than any other grit or impregnated dressing tool.

Many years ago, the Super 716 Series diamond tool was made for dressing large and wide precision grinding wheels on centerless, cylindrical and surface precision grinding machines. They were made to minimize glazing and the closing up of the wheel surface. They were also made to carry the large wheel without taper or the crushing of the bond. It worked better than any other grit or impregnated dressing tool.

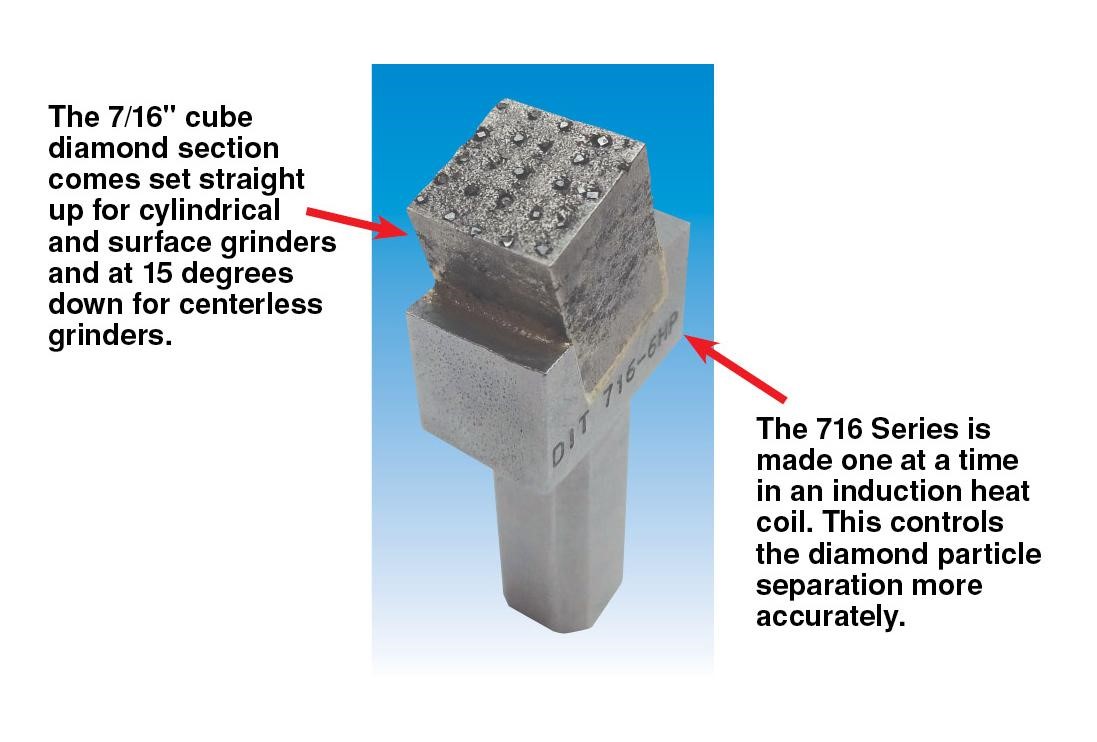

Unlike any grit or impregnated dressing tool the Super 716 Series is made one at a time in an induction heat coil. This controls the diamond particle separation more accurately so they don't flow or clump. The hot-pressed bond retains the diamond mesh more consistently for better dressing control.

The 7/16" cube diamond section comes set straight up for cylindrical and surface grinders and at 15 degrees down for centerless grinders.

It is available in different diamond mesh sizes for the many grinding wheel grit sizes. The new current generation uses blocky natural diamond mesh, which has gone through a new sorting process. This has shown additional new improvements for dressing ceramic abrasive grit wheels.