Contact Details

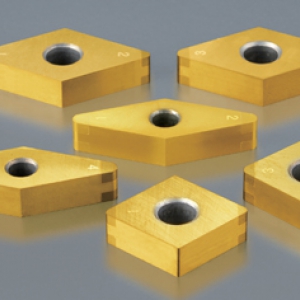

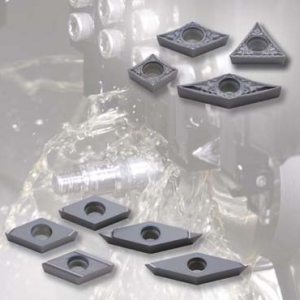

Tungaloy has expanded its DoFeed high feed milling cutter series by adding six LNMU0303UER inserts.

DoFeed is a proven high feed milling cutter series featuring economical double-sided inserts with four cutting edges, offering a wide variety of cutter body diameters and styles.

New LNMU0303UER inserts are available in Size 03 and designed to provide long tool life. These UER inserts are interchangeable with existing ZER inserts on the same cutter body.

The new LNMU0303UER inserts are designed to provide a smaller approach angle than existing LNMU0303ZER inserts when set on the cutter body so that the insert generates thin chips. This chip thinning effect reduces cutting loads, minimizing damage on the cutting edges during machining of exotic materials for longer insert tool life. Also, a small approach angle directs the cutting forces in the axial direction towards the spindle. This amounts to less tool deflection, as there is much less radial force pushing the cutter off its center axis, enabling extremely stable long overhang machining without compromising cutting parameters.

Two chipbreaker styles are available: MJ is suited for general purpose applications and ML boasts sharp cutting edge and low cutting forces. Inserts are offered in AH3225 grade for steel, fracture-resistant AH130 grade for stainless steel and titanium alloys, and AH8015 for machining hardened steel and cast iron.

DoFeed series offers an extensive lineup of inserts and cutter bodies ranging from 16 mm to 50 mm (from .630″ to 2″) diameters to provide high productivity for a wide range of applications.

Related Glossary Terms

- alloys

alloys

Substances having metallic properties and being composed of two or more chemical elements of which at least one is a metal.

- approach angle

approach angle

Angle between the insert’s side-cutting edge and the line perpendicular to the milling cutter’s axis of rotation. Approach angle, which is also known as cutting edge angle, is used with metric units of measurement. See lead angle.

- chipbreaker

chipbreaker

Groove or other tool geometry that breaks chips into small fragments as they come off the workpiece. Designed to prevent chips from becoming so long that they are difficult to control, catch in turning parts and cause safety problems.

- feed

feed

Rate of change of position of the tool as a whole, relative to the workpiece while cutting.

- gang cutting ( milling)

gang cutting ( milling)

Machining with several cutters mounted on a single arbor, generally for simultaneous cutting.

- milling

milling

Machining operation in which metal or other material is removed by applying power to a rotating cutter. In vertical milling, the cutting tool is mounted vertically on the spindle. In horizontal milling, the cutting tool is mounted horizontally, either directly on the spindle or on an arbor. Horizontal milling is further broken down into conventional milling, where the cutter rotates opposite the direction of feed, or “up” into the workpiece; and climb milling, where the cutter rotates in the direction of feed, or “down” into the workpiece. Milling operations include plane or surface milling, endmilling, facemilling, angle milling, form milling and profiling.

- milling cutter

milling cutter

Loosely, any milling tool. Horizontal cutters take the form of plain milling cutters, plain spiral-tooth cutters, helical cutters, side-milling cutters, staggered-tooth side-milling cutters, facemilling cutters, angular cutters, double-angle cutters, convex and concave form-milling cutters, straddle-sprocket cutters, spur-gear cutters, corner-rounding cutters and slitting saws. Vertical cutters use shank-mounted cutting tools, including endmills, T-slot cutters, Woodruff keyseat cutters and dovetail cutters; these may also be used on horizontal mills. See milling.

PRODUCTS

PRODUCTS